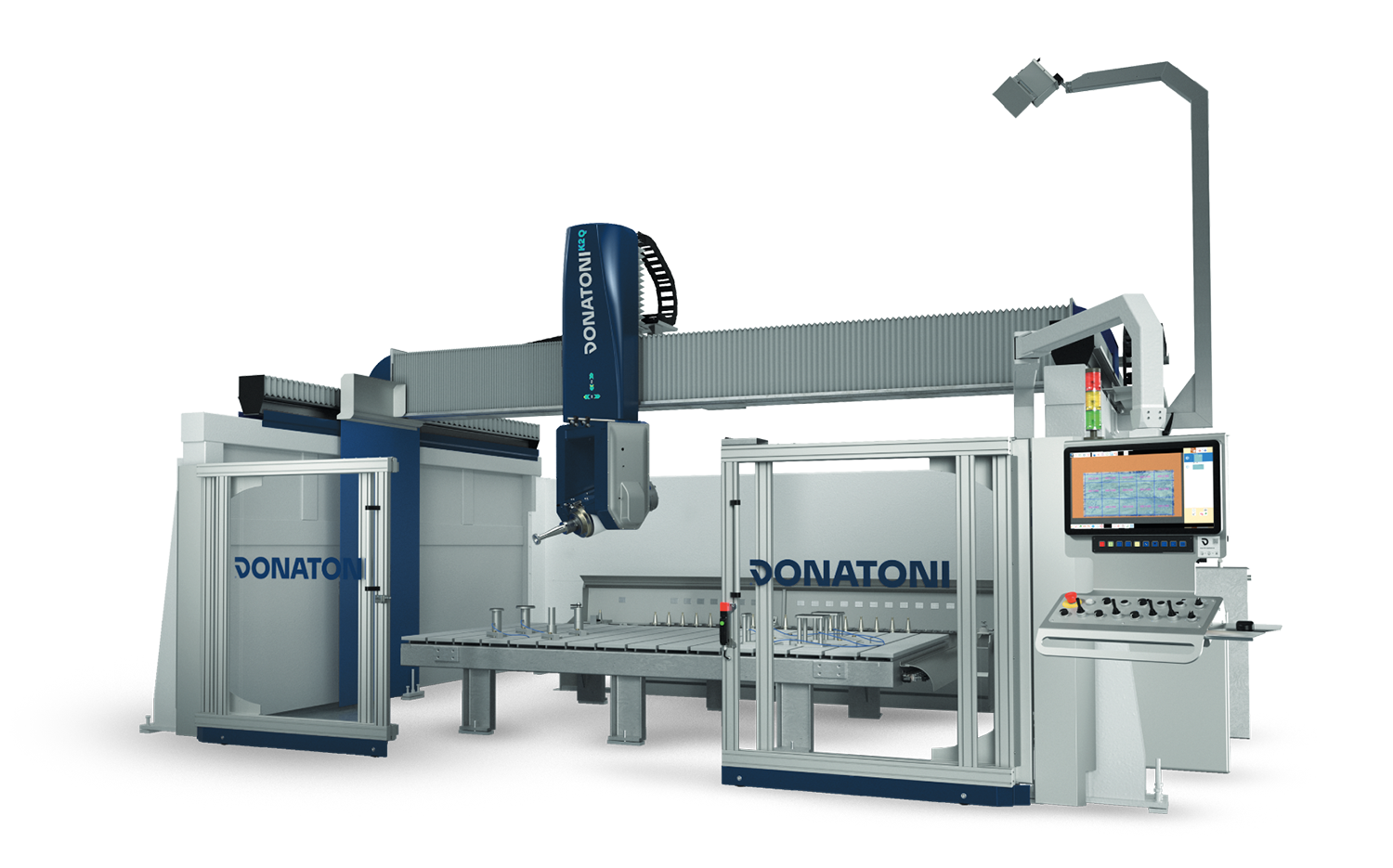

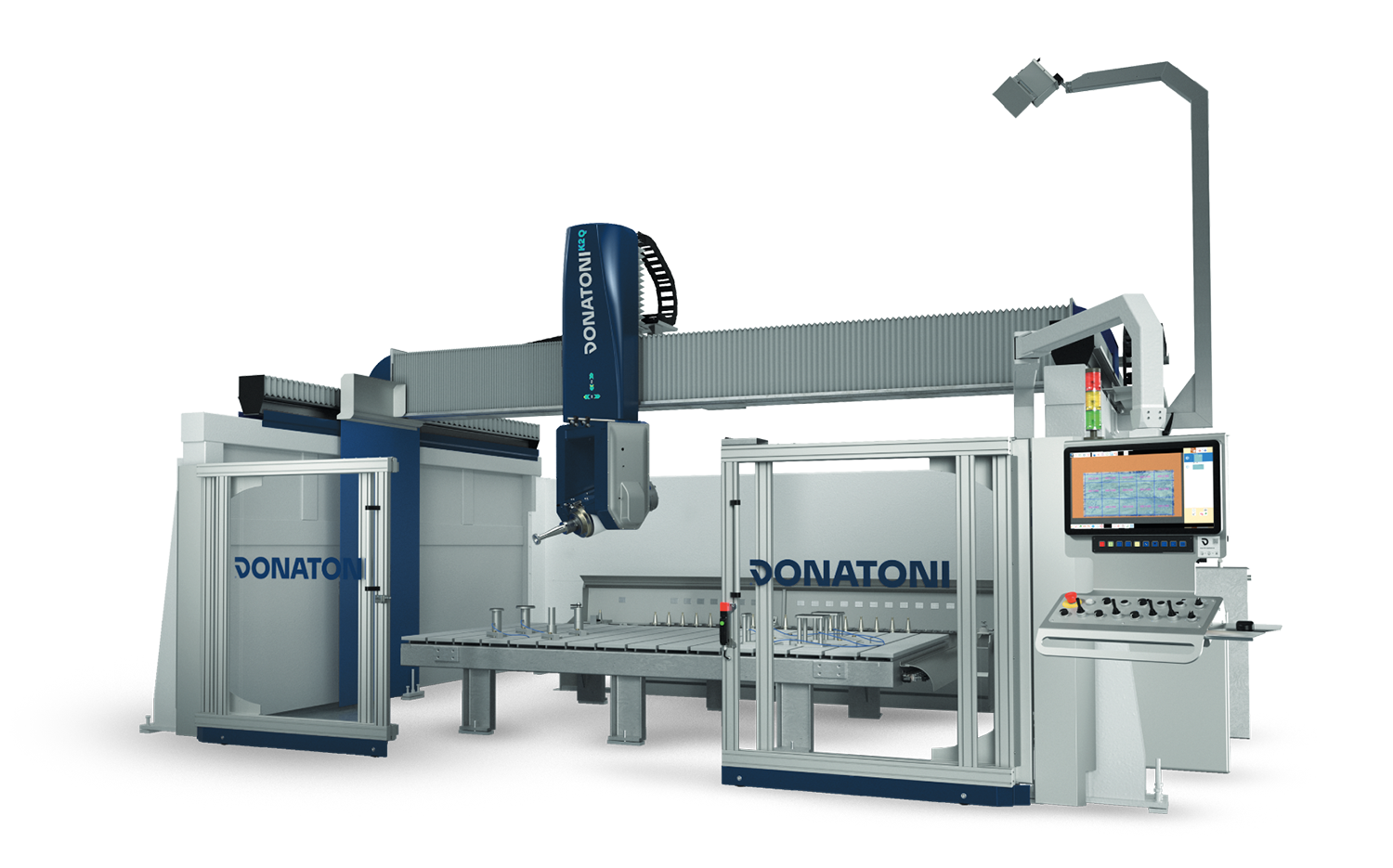

Donatoni

Combining bridge milling and contouring machine

Main features

- These machines combine the typical features of a bridge milling machine with the features of a machining center.

- The Parametrix software and the wooden bench top, with which the K-Series machines are provided, are designed for simple and functional performance of cutting operations, in addition to offering the possibility to make different types of finishes.

- When the bench top is removed, the machine is converted into a 5-axis machining centre – processes are performed directly on the aluminium table – or into a contour milling machine thanks to a kit of suction cups included in the supply.

2 in 1 calibrating and polishing in a single machine

Simple and easy to program

Cnc technology: precision and productivity

Wide range of work processes

Reduced space required

Wide range of accessories and configurations

Flexible production

Main components

Electrospindles K2/K3

Electro-spindles with liquid cooling system from kW 22 / S6, with adjustment of the nr. of revolutions (0-5000/7000), ISO 40 spindle connection, with automatic tool change, head rotating -5 ° + 545 ° and inclinable from 0° to 90 °, mounted on steel carriage

Console

Control consolle on double-jointed on swing arm, manual controls, video 21″ color touch-screen, keyboard and usb port for importing files.

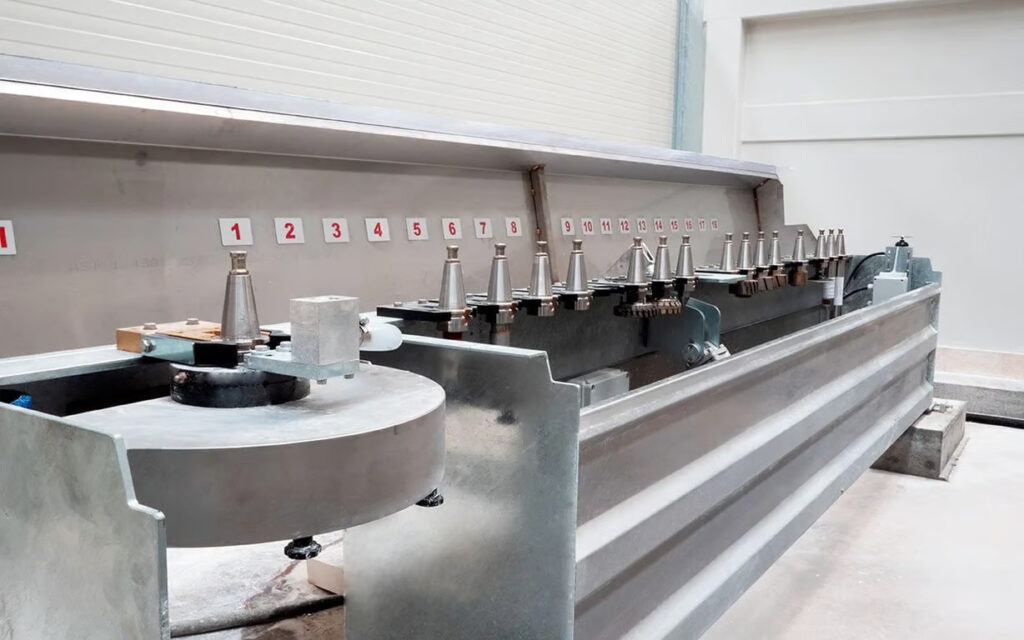

Tool storage 20 positions

Linear tool storage at 20 positions for ISO 40 cones with max. length 600 mm, complete with pneumatic- lifting stainless steel cover (only for ATC or MTB electrospindle)

Fixed workbench with aluminium top

Fixed workbench with alluminium top of 3500 x 2000 mm (137,8 x 78,7 in) for the mechanical fixing of

Steel walls

Sandblasted and painted with 3 coats of paint

Suction cups kit

System for fixing the pieces by means of suction cups and vacuum pump (to be combined with fixed or tilting aluminum bench or platform). H 120 mm.

LED lighting device

Nr. 2 LED lighting devices, positioned perpendicular to the work surface.

They allow a homogeneous diffusion of light to improve the acquisition of images by the camera in case of poorly lit environment.

Oil bath lubrication

Oil bath lubrication for X and Y axis

Move System

Thanks to suction cups it is possible to optimise the use of the slab, avoiding manual movements.

1. Increased efficiency, reduced downtimes

2. Movement of pieces without requiring the operator to intervene

3. Easy to use

4. Makes the machine automatic

5. Less manufacturing waste

6. Can lift up to 500 kg.

2 aluminium suction cups, fitted with 6 sectors of various sizes.

It can be used with blades having a max diameter of 625 mm.

Laser

Cut marker linear laser to display the cutting direction of the disc or to detect the perimeter of the slab.

Watch the K2 Q in action

Photo Gallery

Application sectors

Donatoni K2 Q can be used for :

Software

D-Inside

Manages the integration of the machine with the programming softwares.

Perfection in processing is reached through multiple movements that need o be perfectly coordinated. Every Donatoni machine is created with a smart system for managing work, integrated with all the parts that manage its movements; we call this system D-Inside, the Brain of the machine. D-Inside is an advanced interface but simple from the point of view of use and also ideal for less expert operators as it manages the machine-software system. The D-Inside system offers various programming options and can be interfaced with various types of Donatoni software, such as Parametrix and all the additional modules, CAD-CAM and other software so as to customise the machine according to the customer’s needs.

ISOCAM

The shape processing can be executed in multiple modes.

DONATONI ISOCAM allows files to be created for the execution of straight or concave and convex arc shapes, with vertical and horizontal blades

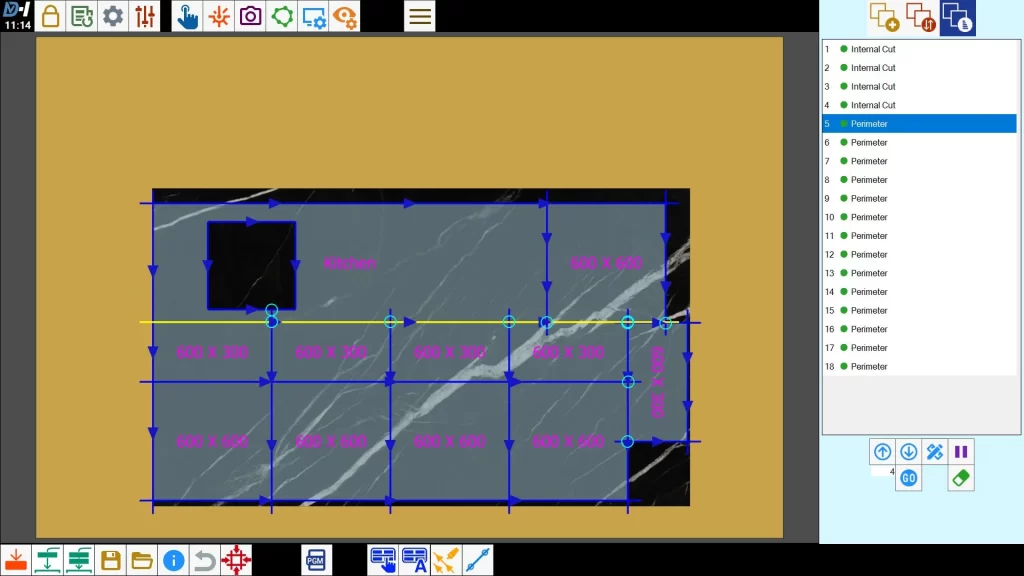

Parametrix

Parametrix is the simple and intuitive Software developed by Donatoni Macchine and designed to optimise the management of cuts of variously-shaped pieces on a slab.

It enables work processes involving cuts with discs, milling cutters and drills, the insertion of straight and curved forms and shapes that have been pre-set or imported from DXF files, and the optimisation of processing times and slab surfaces. Based on the available surface it is possible to set the pieces arrangement and cut sequences. In the software are included anti-collision functions, manual and automatic nesting, production statistics management. Parametrix can be combined with Photoslab and Move-System.

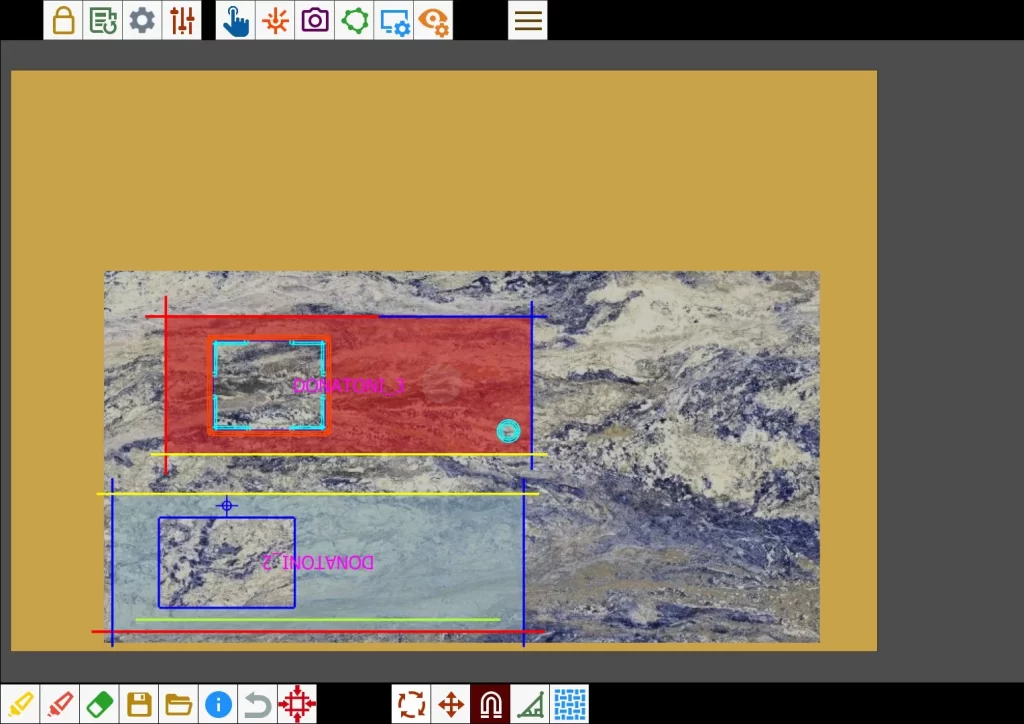

PhotosLab

It allows the surface of slabs placed on the workbench to be automatically detected by camera.

The system optimises the use of slabs and speeds up the positioning of pieces, avoiding the generation of defects and allowing cuts to be made according to the veins of the material.

The software is automatically activated.

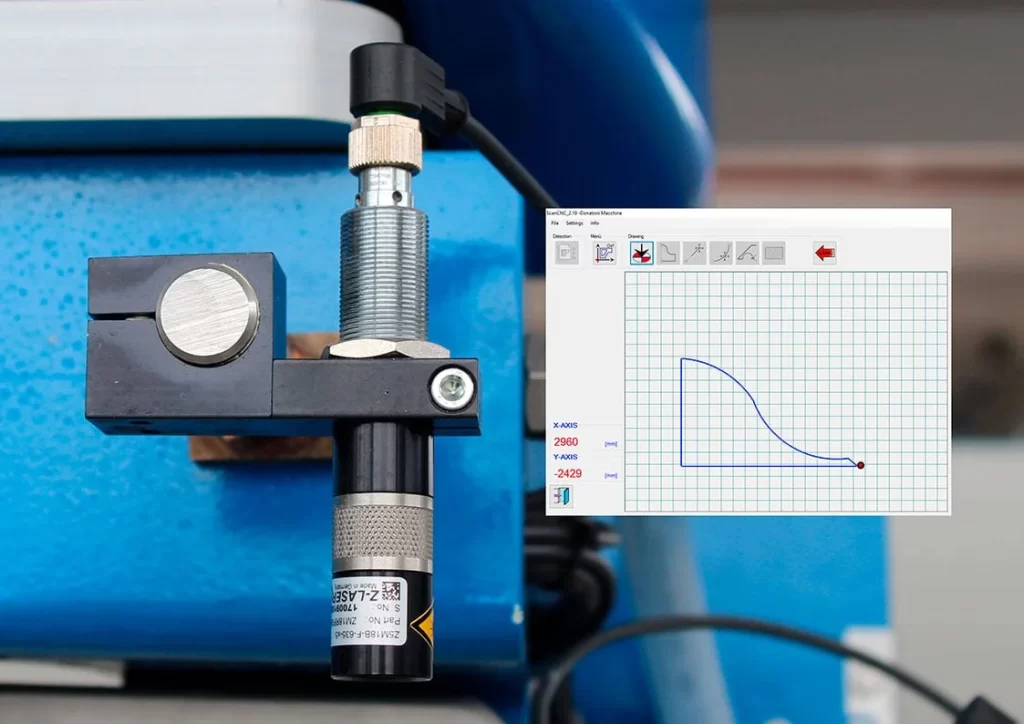

SCAN-CNC

Donatoni Scan CNC makes it possible to reproduce a two-dimensional object such as a kitchen countertop or a step, starting from a cardboard template, or from the damaged object itself.

Thanks to the laser pointer, SCAN CNC detects the shape of the piece placed on the workbench in a few simple steps, perfectly following the edges and creating a DXF file in real time.

After the operation the operator can:

- Process the shape on the touch screen of the machine using the optional Parametrix or Easycut, Easystone Basic or Premium.

- Store the file in the machine PC.

- Store the file in an external PC through a USB device.

Technical data

Additional information

| Number of interpolated axes | N° | |

| Carriage stroke X axis | mm | |

| Maximum carriage speed (X axis) | m/min | |

| Bridge stroke Y axis | mm | |

| Maximum bridge speed (Y axis) | m/min | |

| Vertical stroke Z axis | mm | |

| Maximum head speed (Z axis) | m/min | |

| Blade-carrying head rotation (C axis) | deg | |

| Disc head tilting movement (axis A) | deg | |

| Working table dimensions | mm | |

| Minimum disc diameter | mm | |

| Maximum disc diameter | mm | |

| Maximum cutting depth | mm | |

| Electro spindle motor power | kW | |

| Electrospindle motor nominal torque | Nm | |

| Electro spindle motor speed range | rpm | |

| Cone attach | ISO | |

| Spindle shaft diameter | mm | |

| Motor cooling | ||

| Suction cups stroke | mm | |

| Max. disc dimensions with suction cups | mm | |

| Max weight lift with suction cups | kg | |

| Slab lenght gauges stroke | mm | |

| Max. disc usable with slab lenght gauges | mm | |

| Tool magazine | ||

| Tool support center distance, on magazine | mm | |

| Maximum tool diameter on magazine | mm | |

| Water consumption | l/min | |

| Air Consumption | l/min | |

| Standard electric voltage | V/Hz | |

| Total installed power | kW | |

| Approx. total weight of the machine | kg |