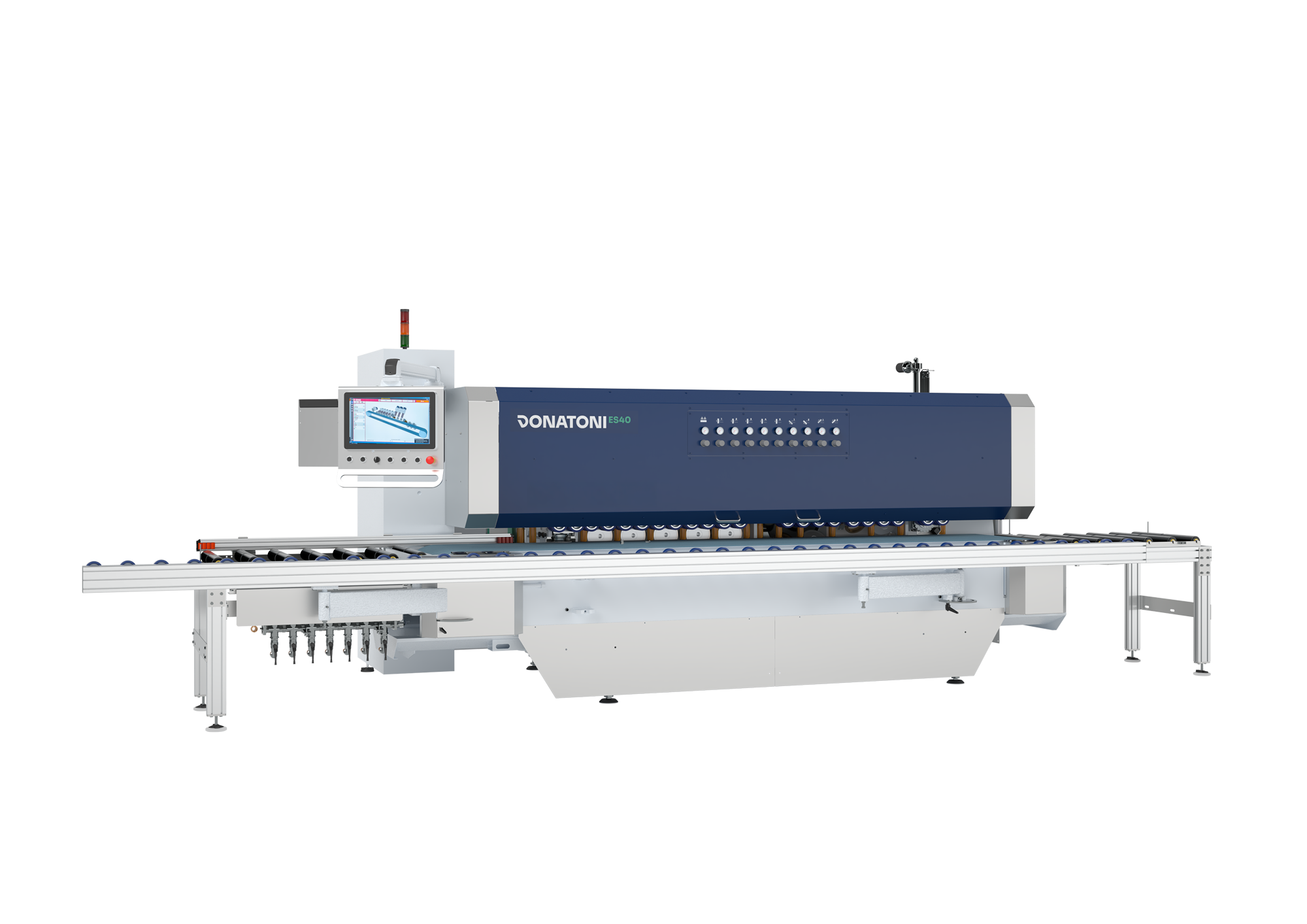

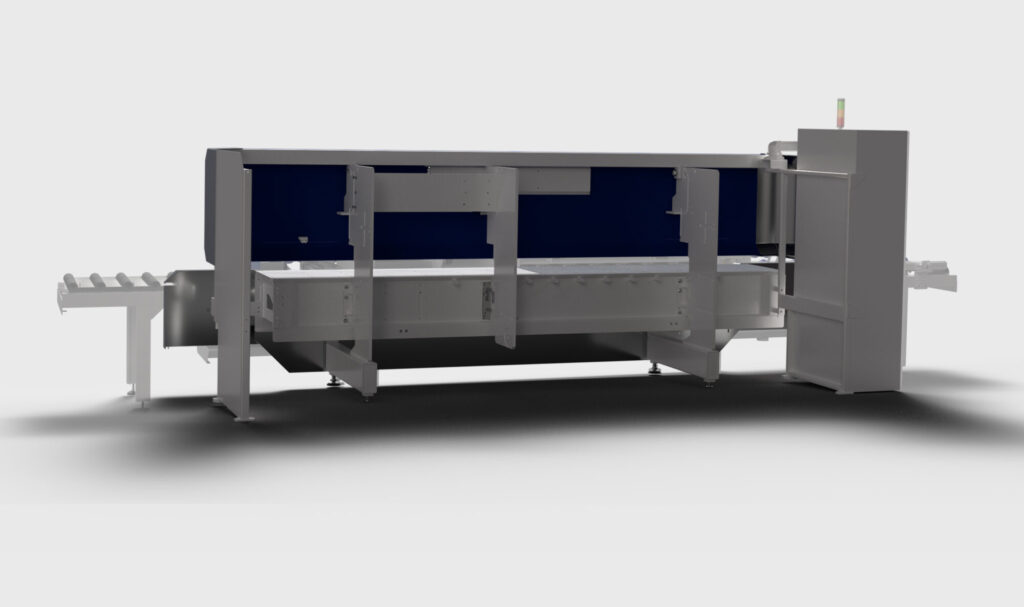

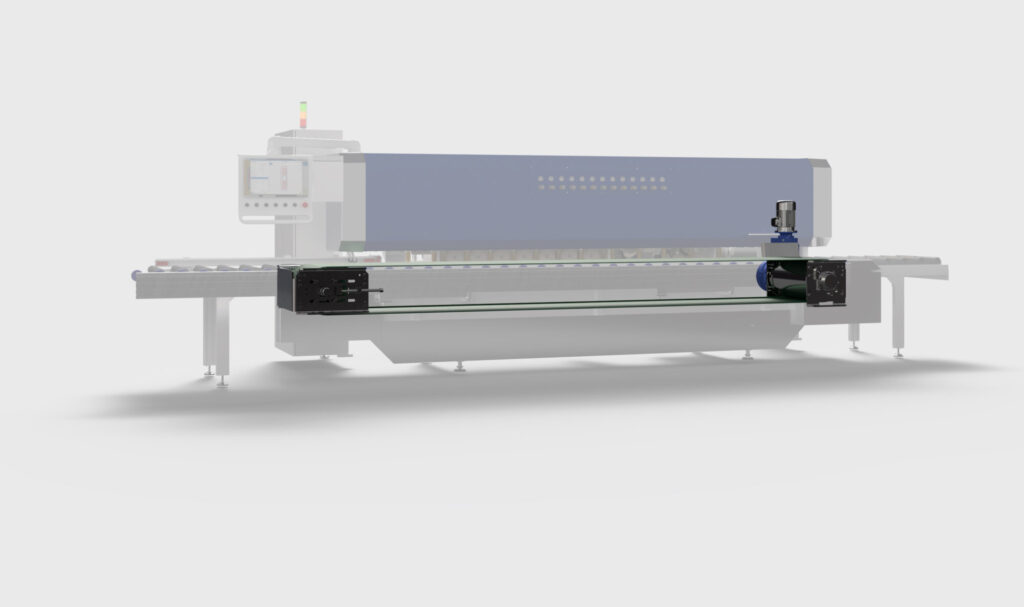

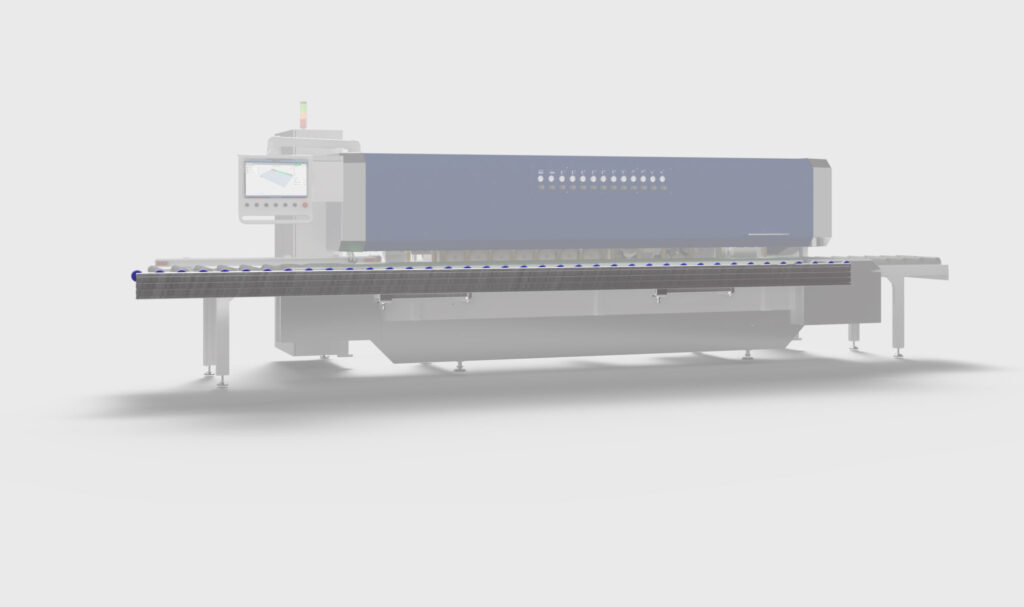

Description

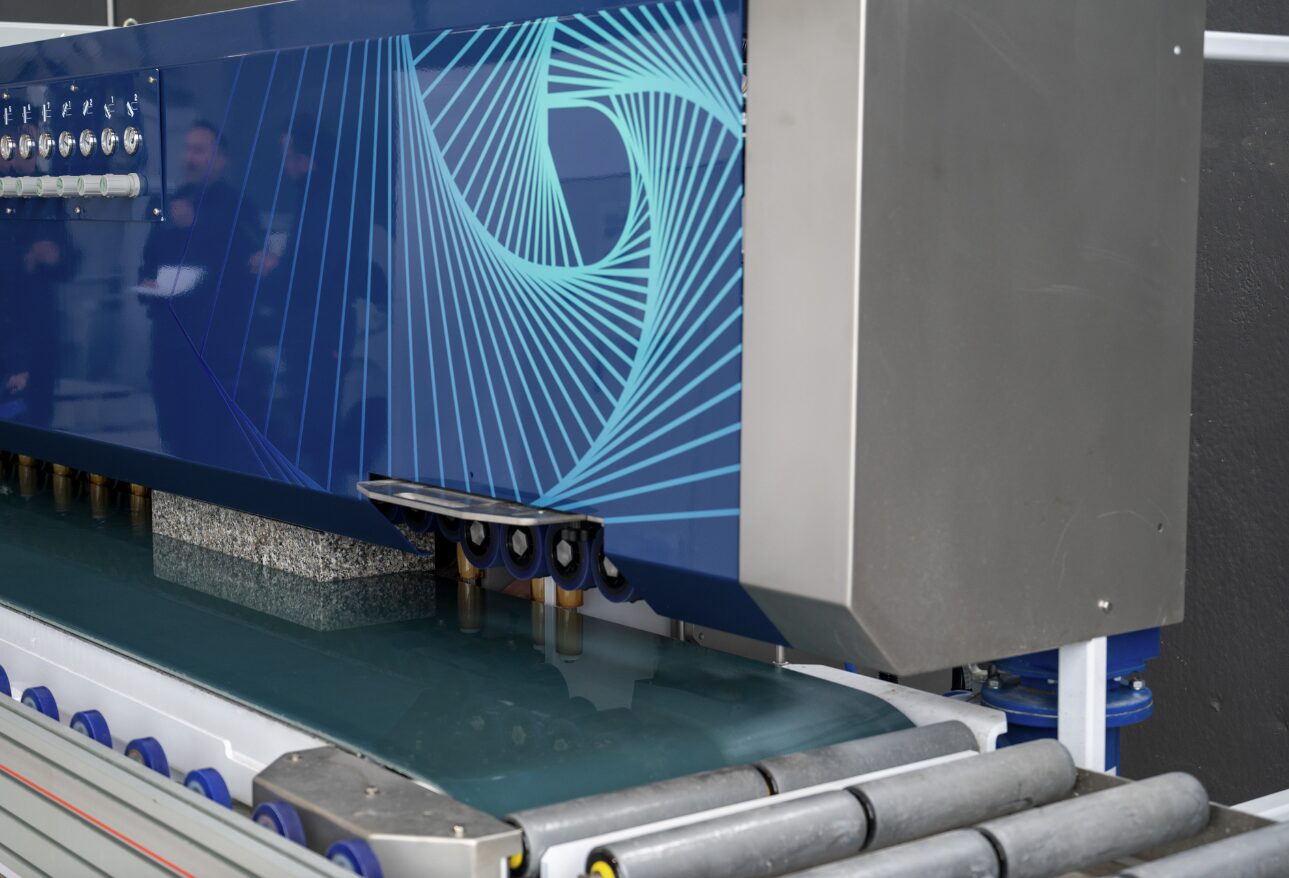

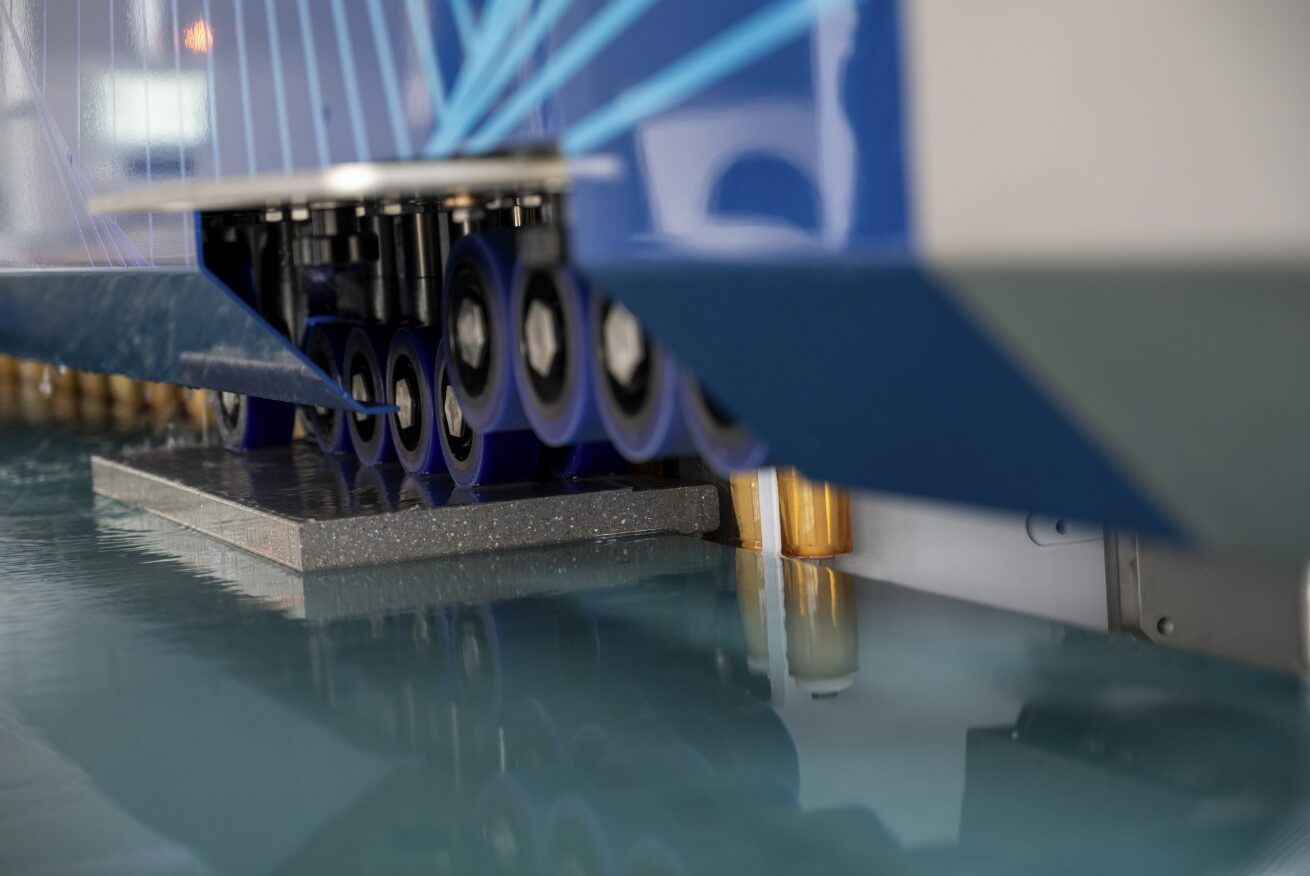

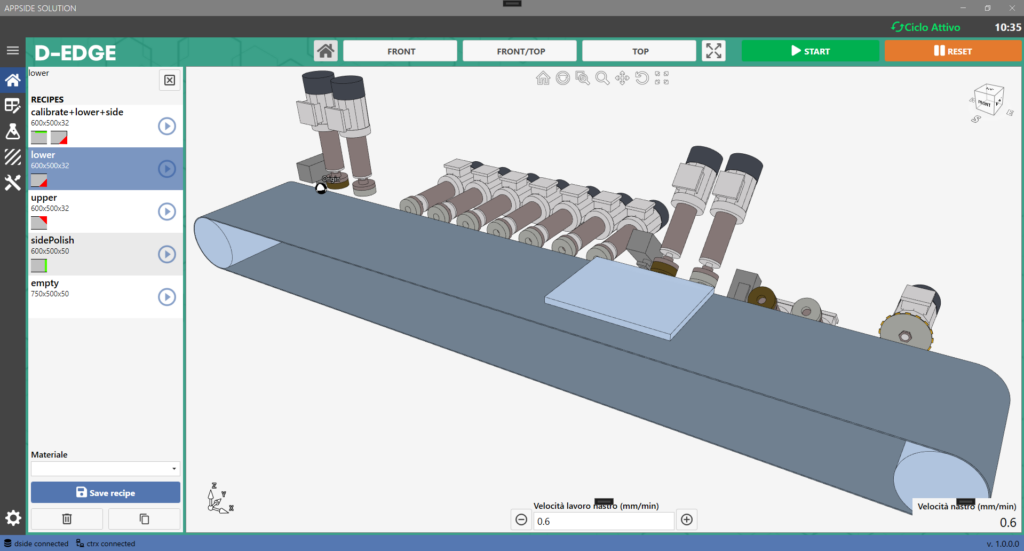

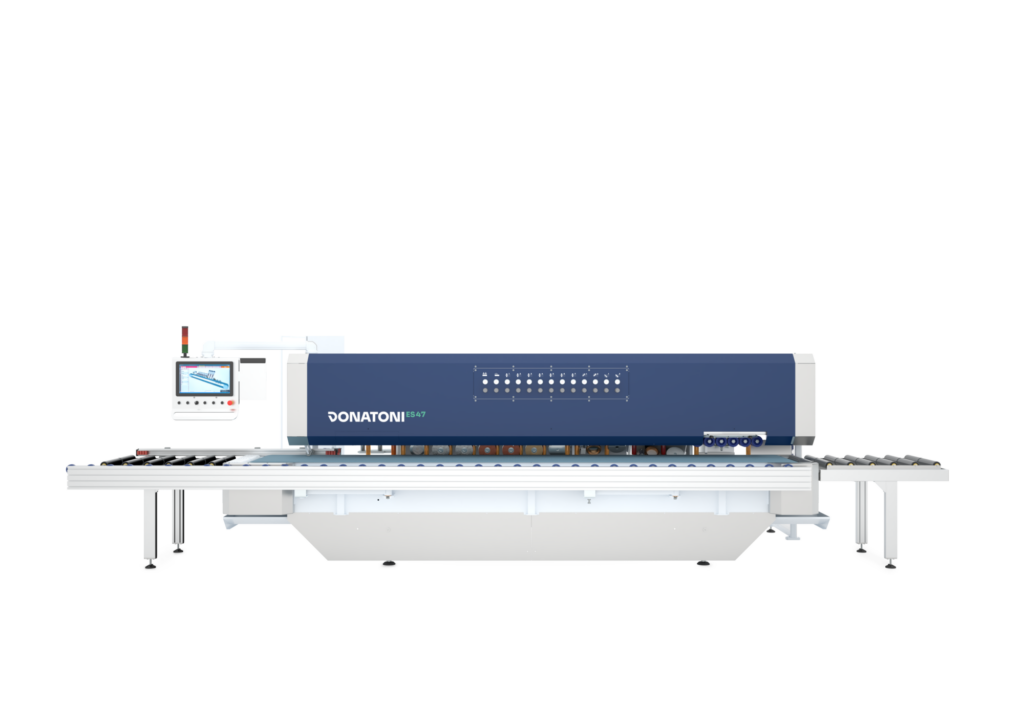

The Donatoni Edge-Polishers range

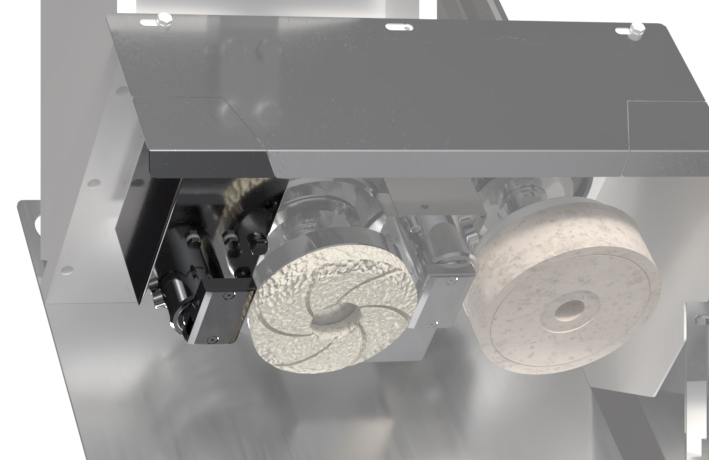

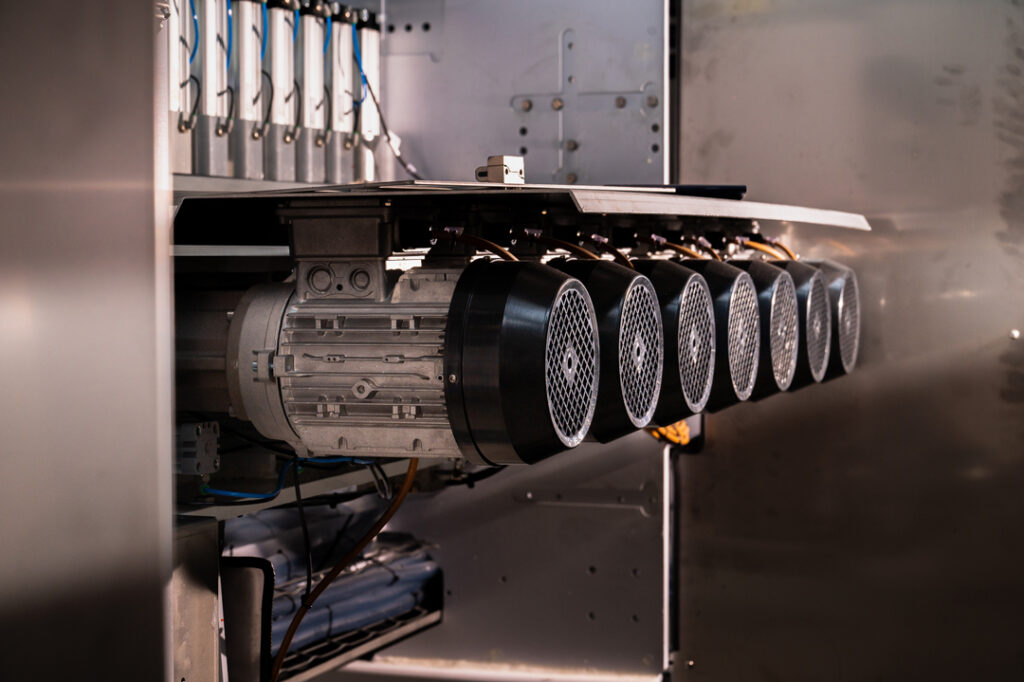

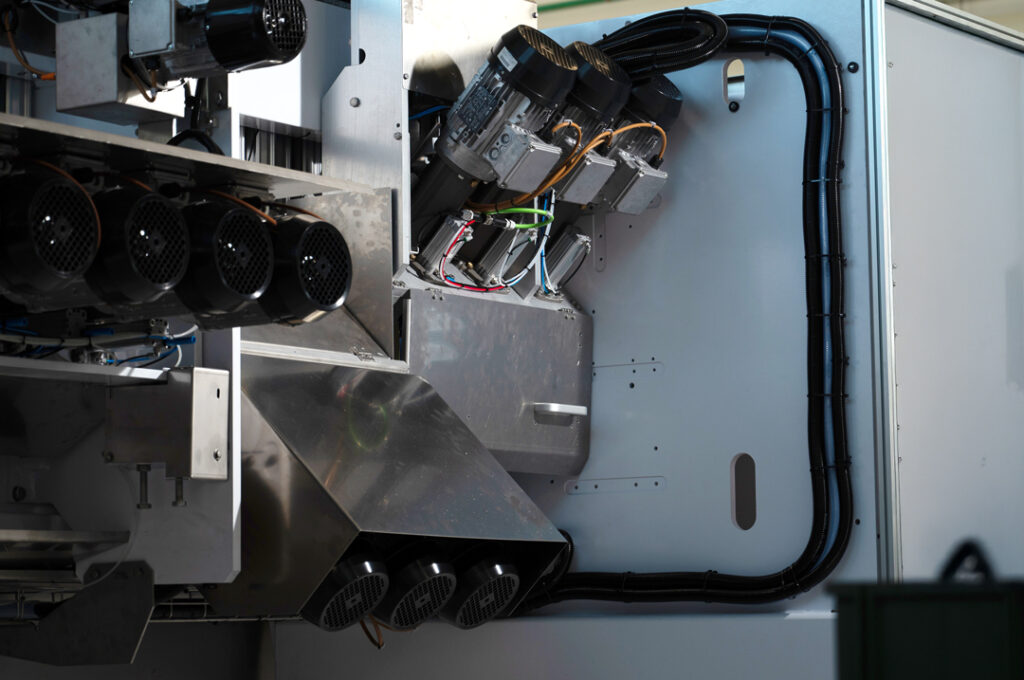

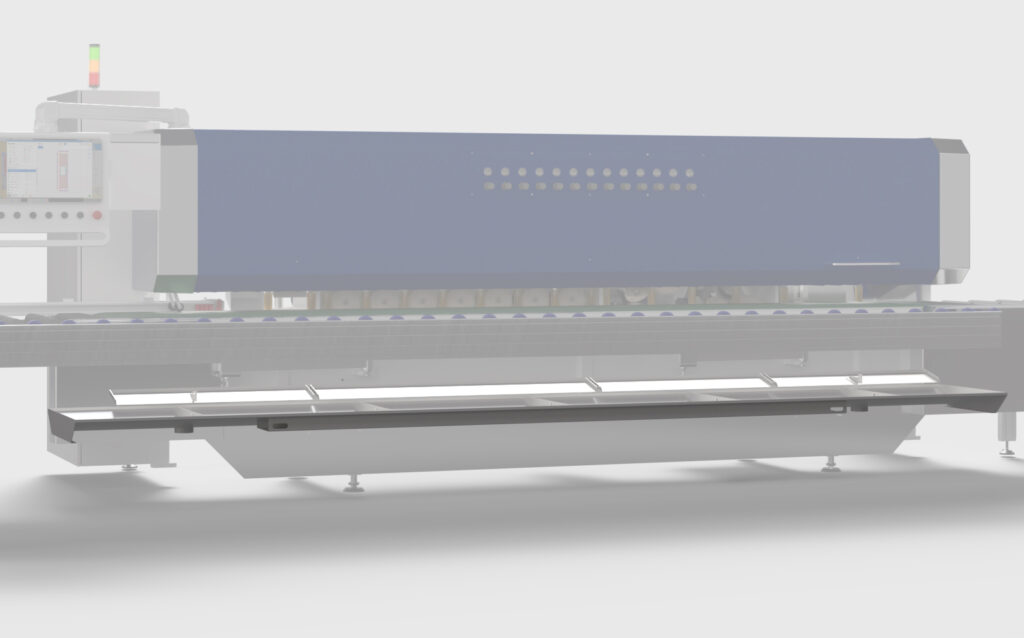

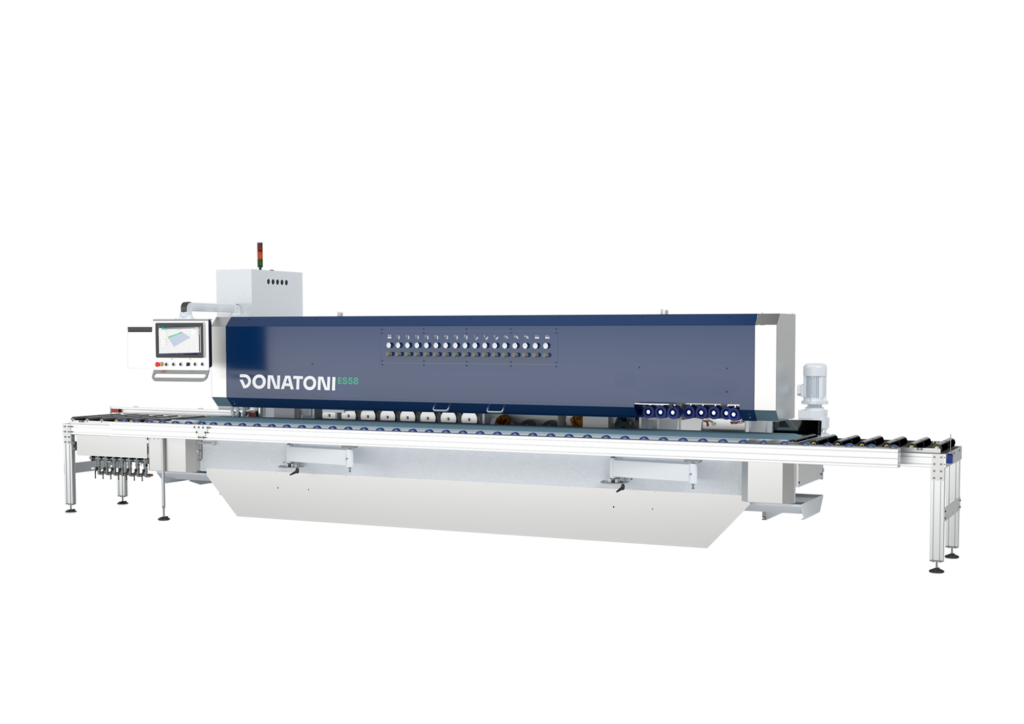

DONATONI ES40 is the new flat-edge edge polisher, with a 3840mm bench, which features automatic positioning of the various processing units depending on the type of material, thickness and processing required. The maximum workable thickness is 50mm and the number of configurable components is 11.