Description

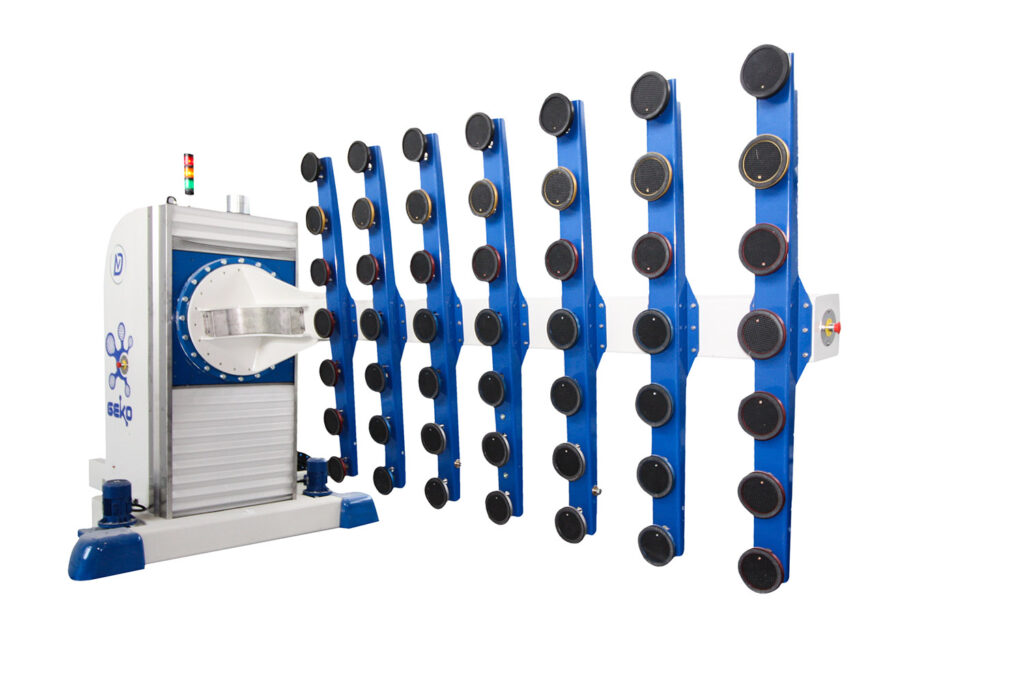

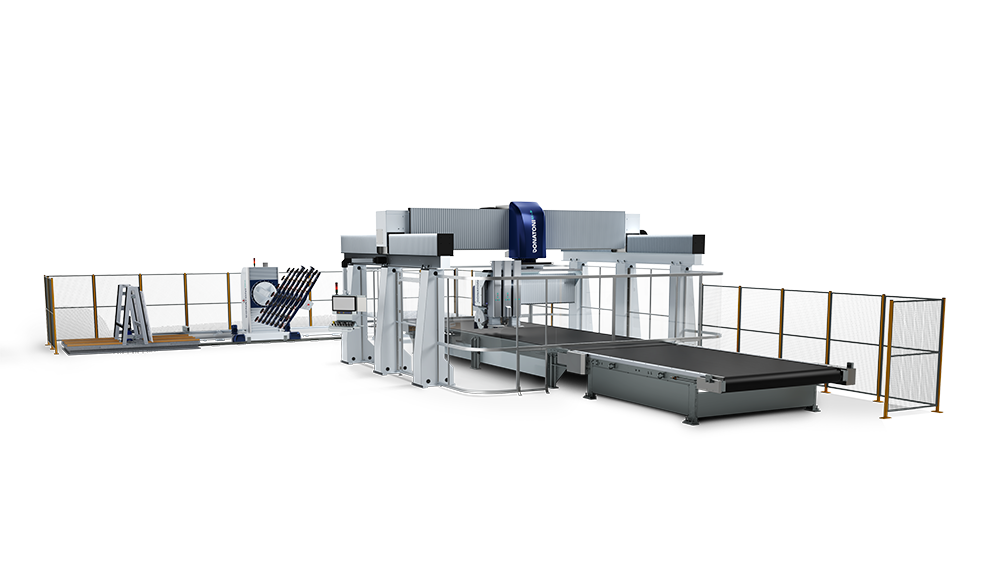

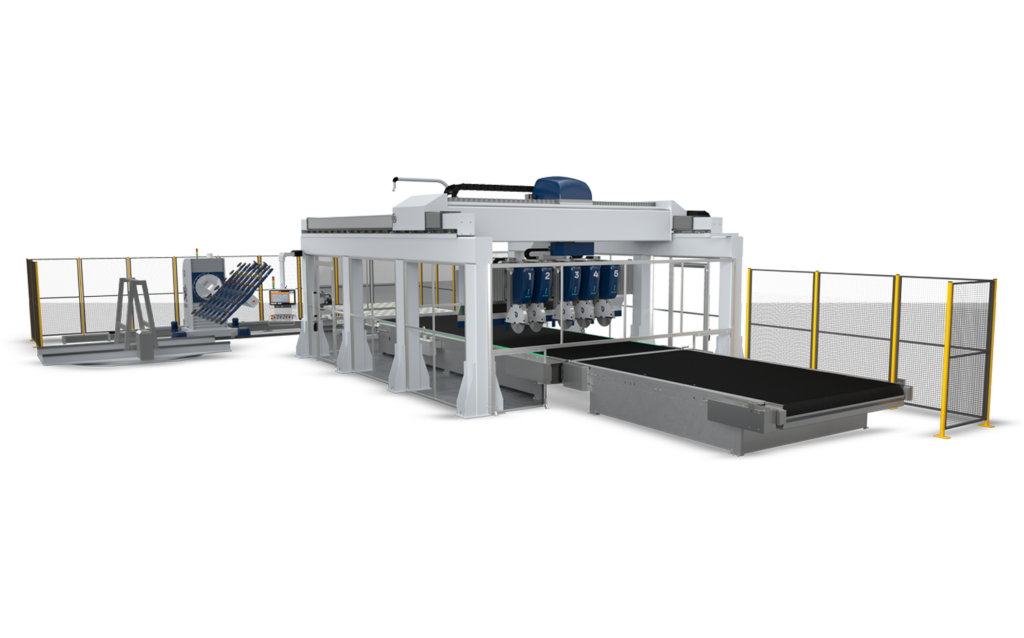

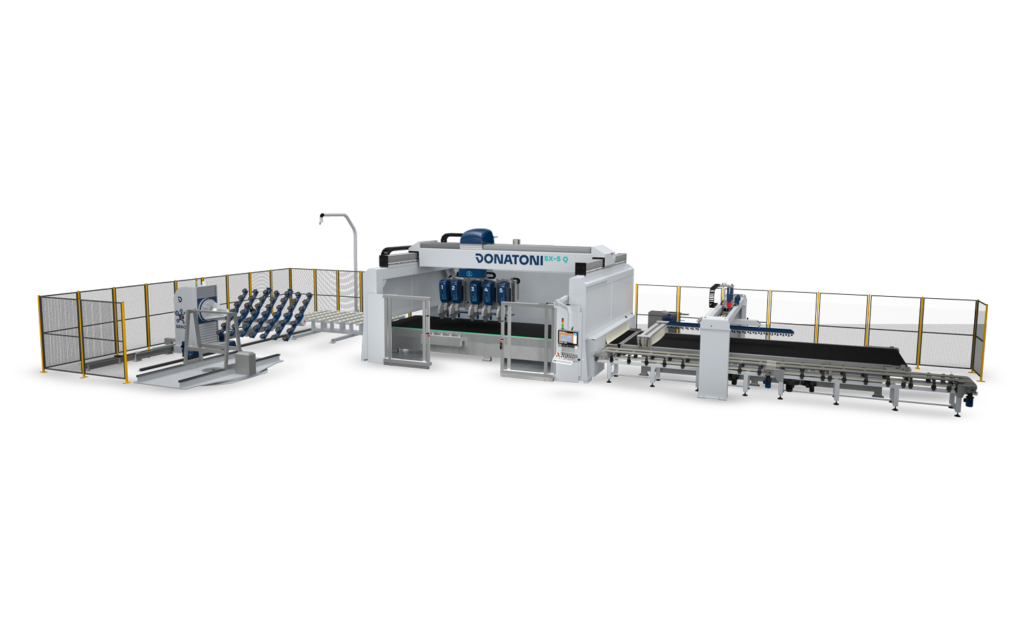

Revolutionary production lines with six cutting units with interpolated axes

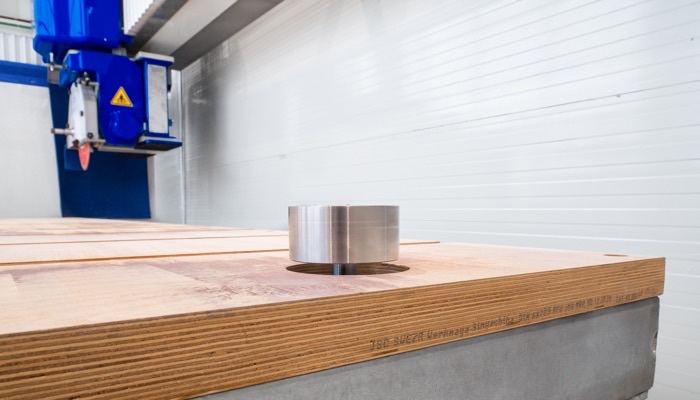

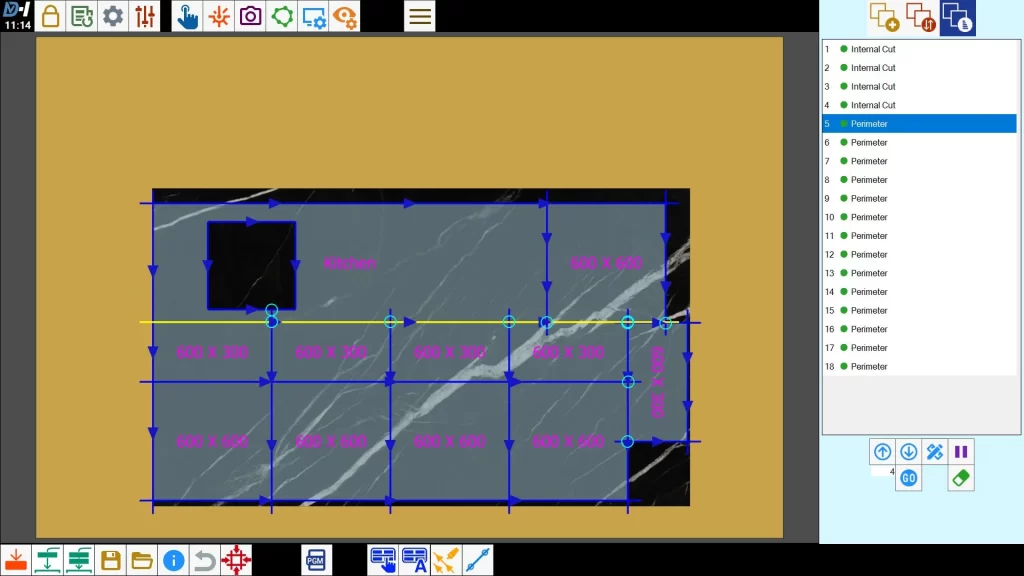

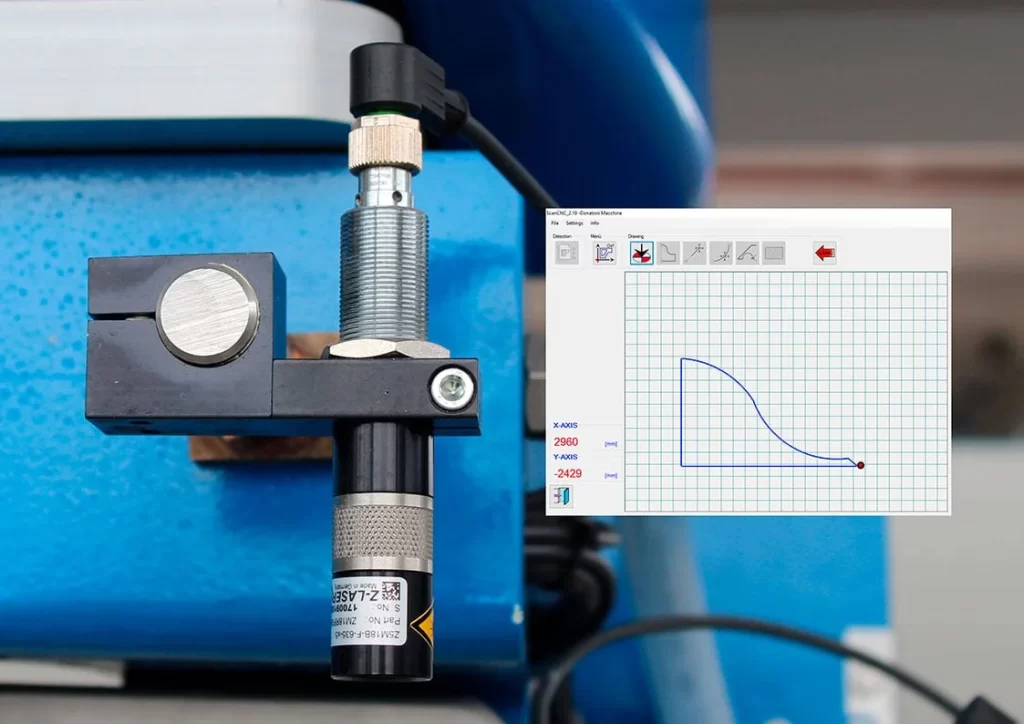

DONATONI SX-6 Q XL represents the peak of production capability in the SX line, featuring six cutting units with nine interpolated axes.

The DONATONI SX Q XL systems enable mass production while mantaining the capability to work on a wide range of floorings and claddings.