Description

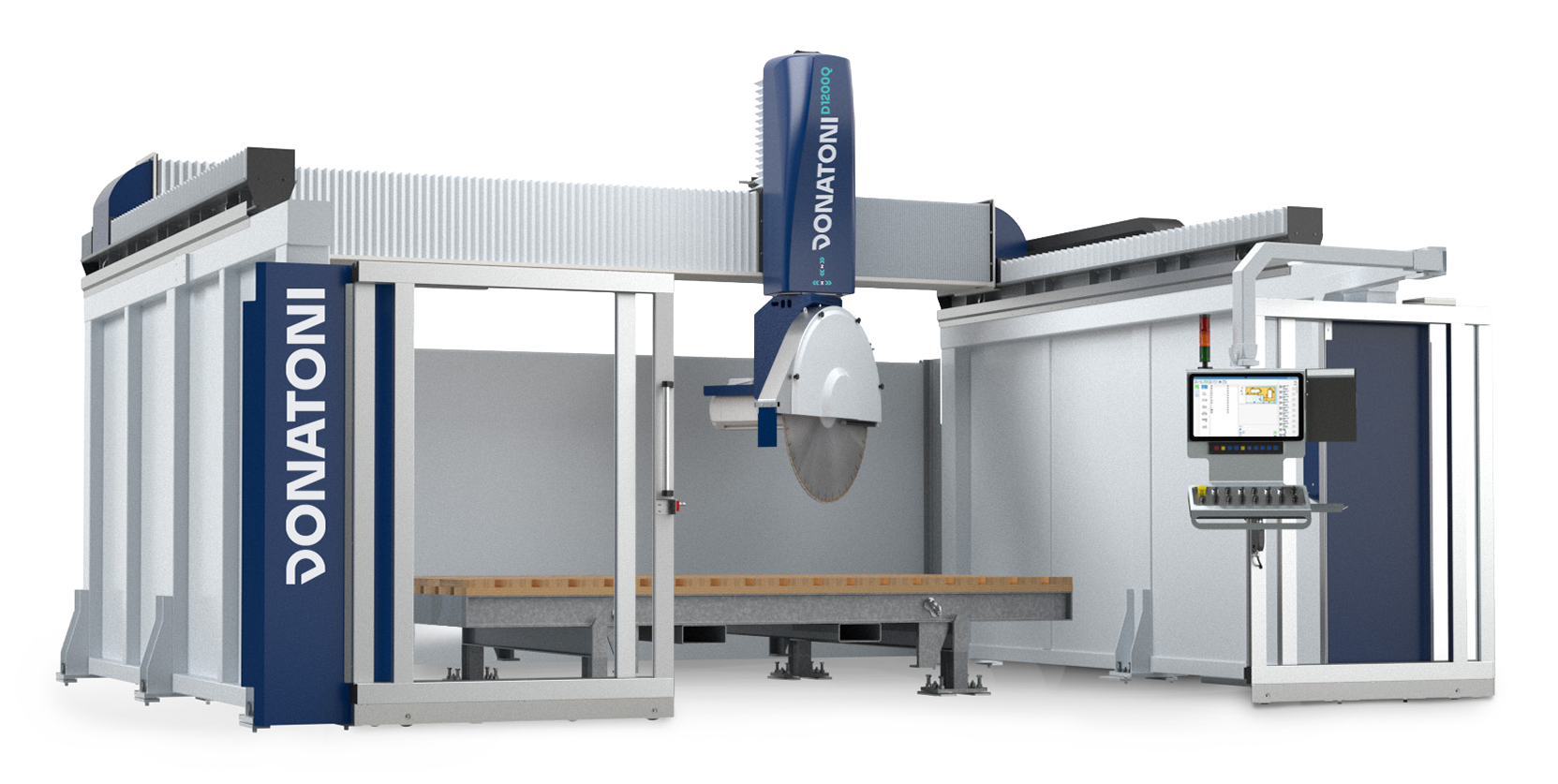

DONATONI D1200Q It is a 5-axis interpolated numerically controlled cutting and shaping centre with a 1200 mm disc and a 600 mm Z-axis stroke; the rotating disc head can be tilted from 0° to 90° to perform cuts up to 470 mm deep.

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

DONATONI D1200Q It is a 5-axis interpolated numerically controlled cutting and shaping centre with a 1200 mm disc and a 600 mm Z-axis stroke; the rotating disc head can be tilted from 0° to 90° to perform cuts up to 470 mm deep.

TECHNICAL SPECIFICATIONS AND BASIC EQUIPMENT OF THE MACHINE:

/ D725Q base structure

/ Rotating head -5°/+365°

/ Bevel cuts 0°/+90°

/ Special long bridge for HS

/ X stroke = 3,800 mm

/ Y stroke = 2,950 mm

/ Z stroke=600 mm

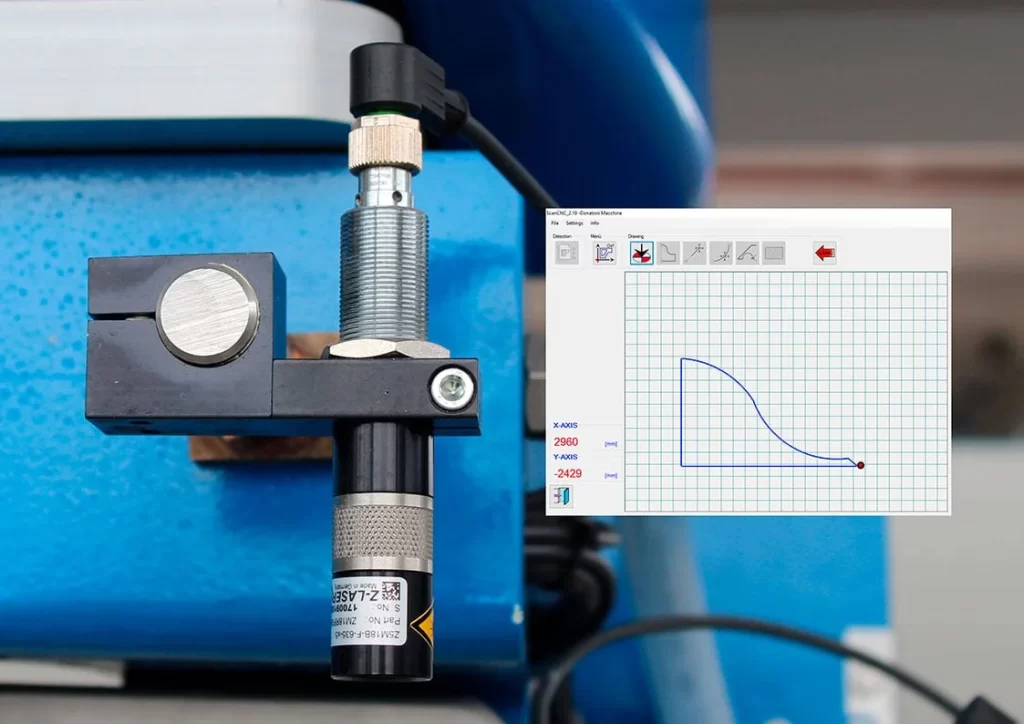

/ Line laser

/ Base bench: BFPL 3500x2000x650mm – 4T

CONFIGURABLE OPTIONS:

/ Different Y strokes

/ Iron walls

/ BRPL 3500x2000x650mm tilting bench – 4T

/ Removable benches 3500x2000x650mm + floor structure

/ Photo plate

/ Disc presetting

/ Handheld terminal

/ Levelling extension kit

/ ISOCAM

Control consolle on double-jointed on swing arm, manual controls, video 21″ color touch-screen, keyboard and usb port for importing files.

The cross-shaped laser is the ideal solution for accurate suction cup placement. The laser is mounted on the spindle assembly and provides for accuracy and efficiency during the machining process.

Oil bath lubrication for X and Y axis

Shaping can be done in the roughing (combing) and the finishing (brushing) modes, but also in the combined mode.

ISOCAM is the software that allows files to be created for the execution of straight or concave and convex arc shaping with both vertical and horizontal discs.

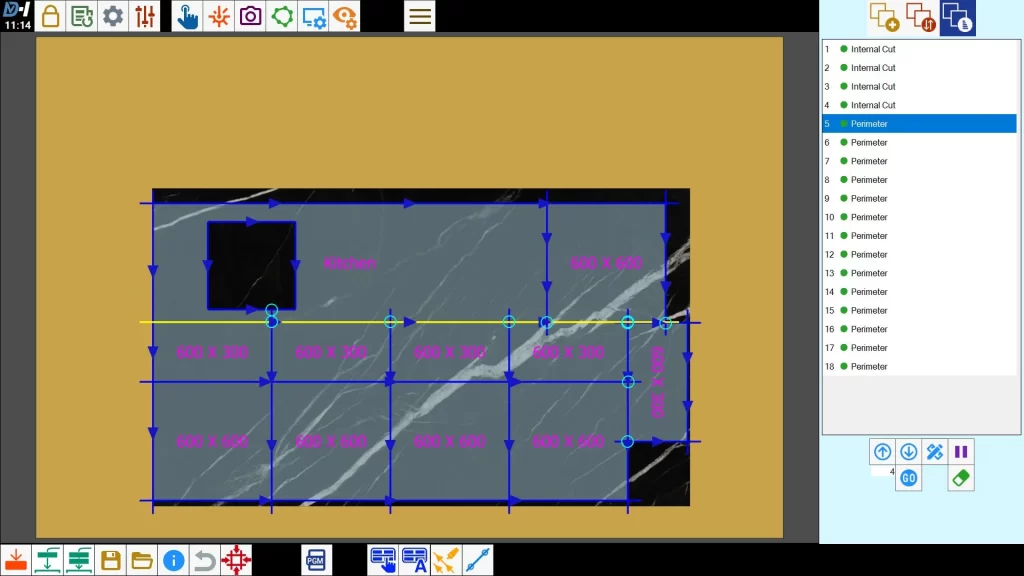

Parametrix is the simple and intuitive Software developed by Donatoni Macchine and designed to optimise the management of cuts of variously-shaped pieces on a slab.

It enables work processes involving cuts with discs, milling cutters and drills, the insertion of straight and curved forms and shapes that have been pre-set or imported from DXF files, and the optimisation of processing times and slab surfaces. Based on the available surface it is possible to set the pieces arrangement and cut sequences. In the software are included anti-collision functions, manual and automatic nesting, production statistics management. Parametrix can be combined with Photoslab and Move-System.

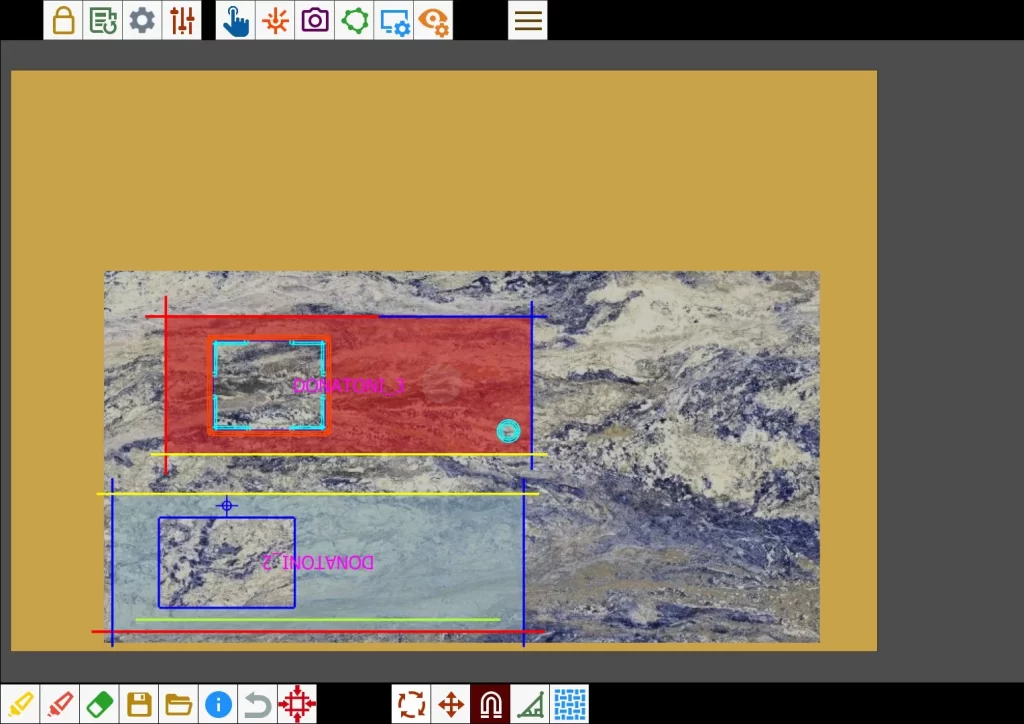

It allows the surface of slabs placed on the workbench to be automatically detected by camera.

The system optimises the use of slabs and speeds up the positioning of pieces, avoiding the generation of defects and allowing cuts to be made according to the veins of the material.

The software is automatically activated.

Donatoni Scan CNC makes it possible to reproduce a two-dimensional object such as a kitchen countertop or a step, starting from a cardboard template, or from the damaged object itself.

Thanks to the laser pointer, SCAN CNC detects the shape of the piece placed on the workbench in a few simple steps, perfectly following the edges and creating a DXF file in real time.

After the operation the operator can:

DONATONI D1200Q It is a 5-axis interpolated numerically controlled cutting and shaping centre with a 1200 mm disc and a 600 mm Z-axis stroke; the rotating disc head can be tilted from 0° to 90° to perform cuts up to 470 mm deep.