Description

DONATONI C3.44 is a 3-axis interpolated CNC machining centre, ideal for all companies that require a machine capable of guaranteeing high-quality finishes on marble, stone, granite, quartz agglomerate and ceramic materials.

DONATONI C3.44 is a 3-axis interpolated CNC machining centre, ideal for all companies that require a machine capable of guaranteeing high-quality finishes on marble, stone, granite, quartz agglomerate and ceramic materials.

Powerful and versatile, this centre can control complex machining processes and at the same time guarantee high production standards. The machine with the largest working dimensions of the C-SERIES guarantees extremely rigid mechanics for companies that need to process larger-sized pieces.

The integrated Cad-Cam software helps DONATONI C3.44 make the best out of its potential and manage with ease even the most demanding requirements of the market.

Compactness, rigidity, and long-term durability. The self-supporting welded steel frame is galvanized and painted to ensure maximum long-term protection. The structure is easy to position thanks to the lifting holes for crane or gantry. The ground placement is safe and stable thanks to adjustable feet. This is the most functional solution to ensure quick machine start-up.

Innovative 18 kW electrospindle, 12000 rpm. The hollow shaft allows internal water flow, ensuring optimal cooling via an external heat exchanger. The electrospindle is equipped with an internal encoder for spindle alignment with ISO 40 tool holder cones. The cones are loaded automatically with a pneumatic system that opens/closes the clamp.

Steel tool holder integrated into the monobloc, designed to hold ISO 40 tool holder cones. The pneumatic system opens and closes the magazine, protecting tools during operation. Several configurations are available depending on the machine model. All include tool presetting.

Front safety barriers with closing system ensure high safety standards. Designed to maintain maximum visibility and minimize obstruction. The closure consists of a 2+2 door system. Opening methods vary by model.

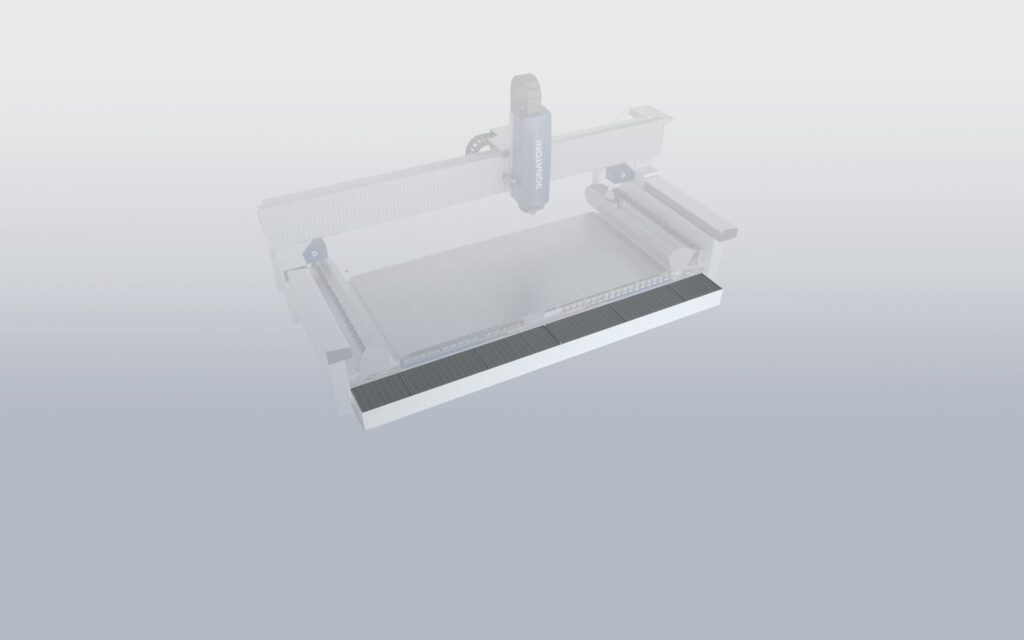

Worktable made of extruded aluminum slats offering excellent performance. A system of plastic profiles allows the use of double-effect suction cups over the entire table area.

A system of water tanks runs along the table’s perimeter, collecting and draining processing water efficiently. This keeps the workspace clean and dry, ideal for uninterrupted productivity.

System with one or two vacuum bars designed for optimal suction and blow control of suction cups or stops. Movement of cups and telescopic stops is easily managed via foot switches. Each bar supports up to 11 double-effect suction cups and 3 stops.

The control panel is the basic tool for machine use and programming. It’s designed to be intuitive, featuring an innovative console with a large 21” touch screen. The ergonomic structure makes the machine easy to use.

The cross-shaped laser is the ideal solution for accurate suction cup placement. The laser is mounted on the spindle assembly and provides for accuracy and efficiency during the machining process.

The handheld terminal includes buttons for manually moving all machine axes at low speed (in steps or “JOG” mode).

A tilting system for the spindle axis, optional for C3.44, ideal for performing angled cuts with maximum precision (e.g., angled recesses). The tilt range is ±3°, managed automatically by a pneumatic piston. The angle is manually adjustable via screws.

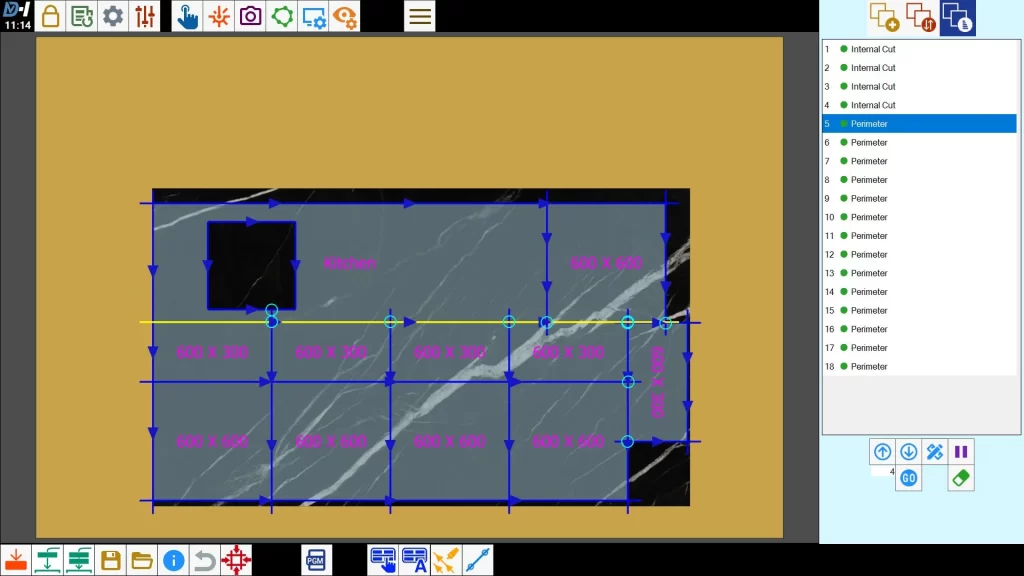

Parametrix is the simple and intuitive Software developed by Donatoni Macchine and designed to optimise the management of cuts of variously-shaped pieces on a slab.

It enables work processes involving cuts with discs, milling cutters and drills, the insertion of straight and curved forms and shapes that have been pre-set or imported from DXF files, and the optimisation of processing times and slab surfaces. Based on the available surface it is possible to set the pieces arrangement and cut sequences. In the software are included anti-collision functions, manual and automatic nesting, production statistics management. Parametrix can be combined with Photoslab and Move-System.

Easystone is a software for the creation of design products, statues and architectural projects ranging from simple to complex. It is a professional CAD-CAM software specifically designed for stone processing.

DONATONI C3.44 is a 3-axis interpolated CNC machining centre, ideal for all companies that require a machine capable of guaranteeing high-quality finishes on marble, stone, granite, quartz agglomerate and ceramic materials.

| Number of interpolated axes | N° | |

| Carriage stroke X axis | mm | |

| Maximum carriage speed (X axis) | m / min | |

| Bridge stroke Y axis | mm | |

| Maximum bridge speed (Y axis) | m / min | |

| Vertical stroke Z axis | mm | |

| Maximum head speed (Z axis) | m / min | |

| Working table dimensions | mm | |

| Height from the ground of the workbench | mm | |

| ISO 40 electro spindle motor power | kW | |

| ISO 40 electro spindle motor nominal torque | Nm | |

| TOOL electro spindle motor speed range | rpm | |

| number of suction cups per work area | N° | |

| Magazines tool positions | N° | |

| Clear water consumption | l/min | |

| Recirculated water consumption | l/min | |

| Air Consumption | l/m | |

| Standard electric voltage | V/Hz | |

| Total installed power | kW | |

| Overall dimensions (W/L/H) | mm | |

| Machine weight | kg |

Error: Contact form not found.