Description

Innovative CNC multi-spindle cutting centres

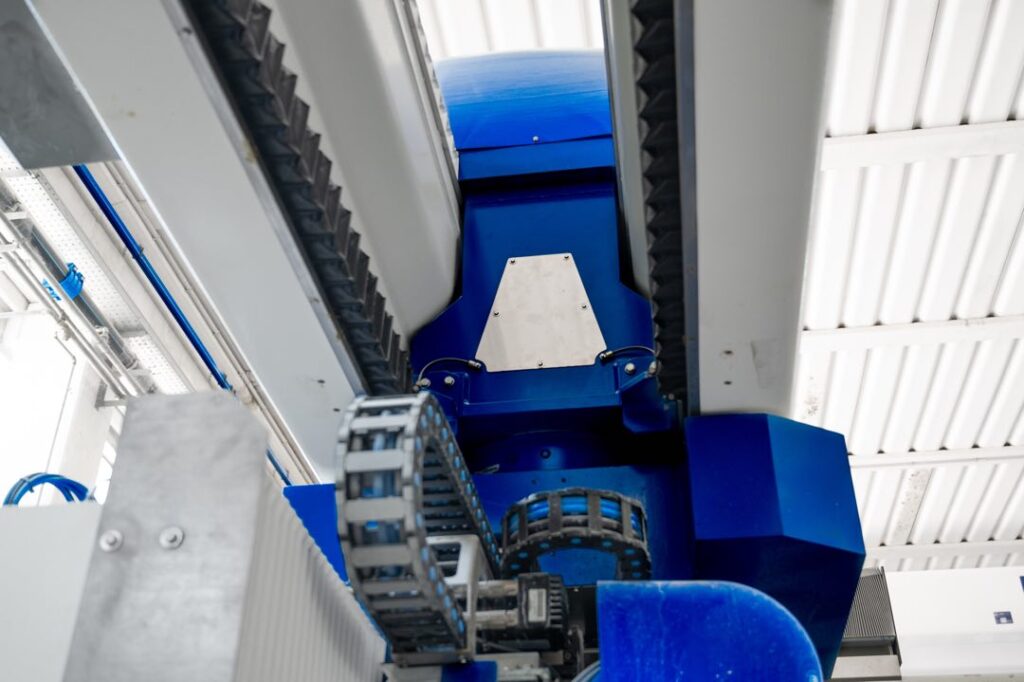

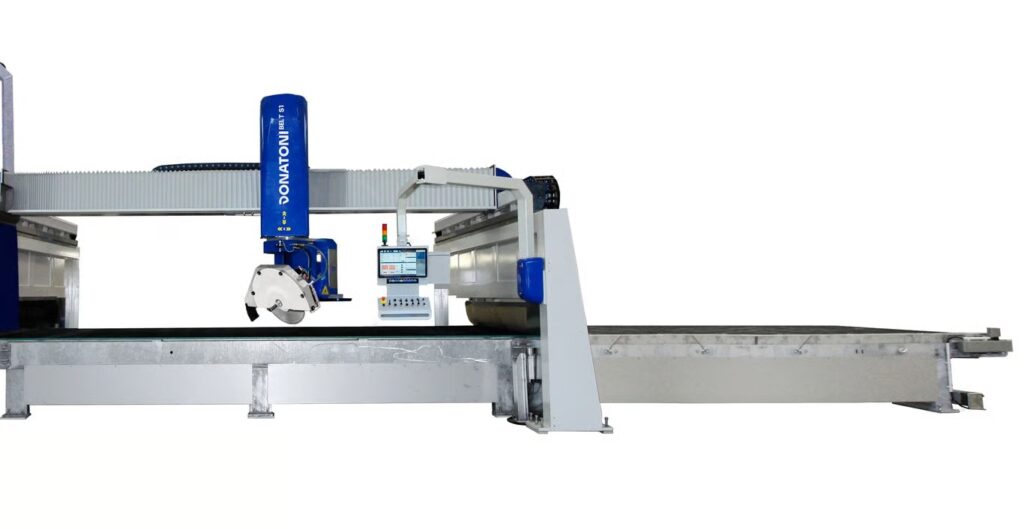

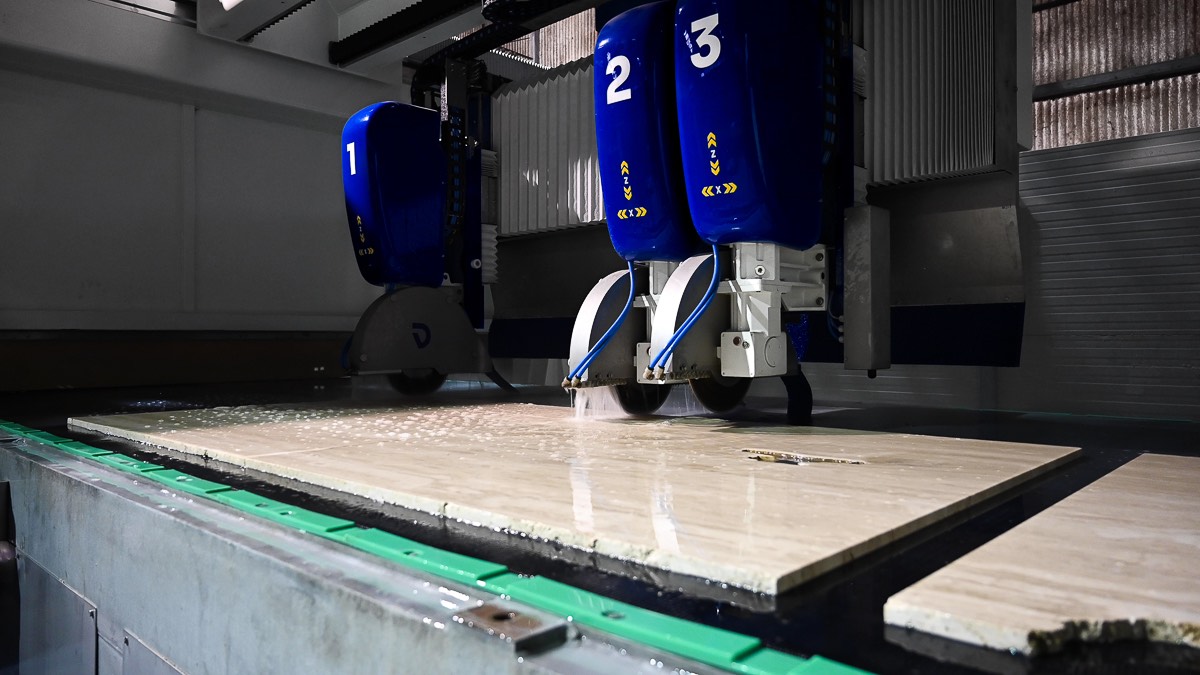

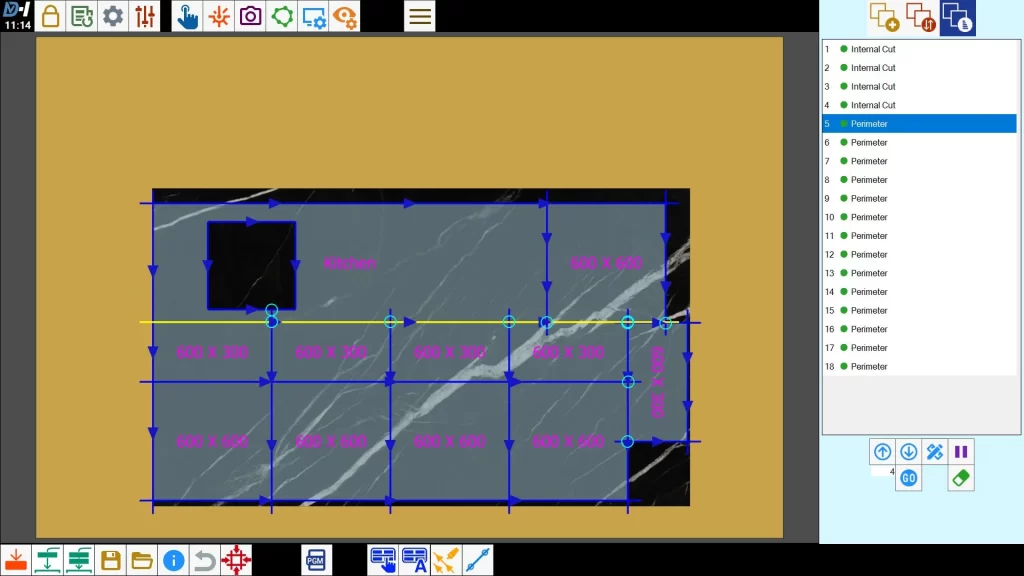

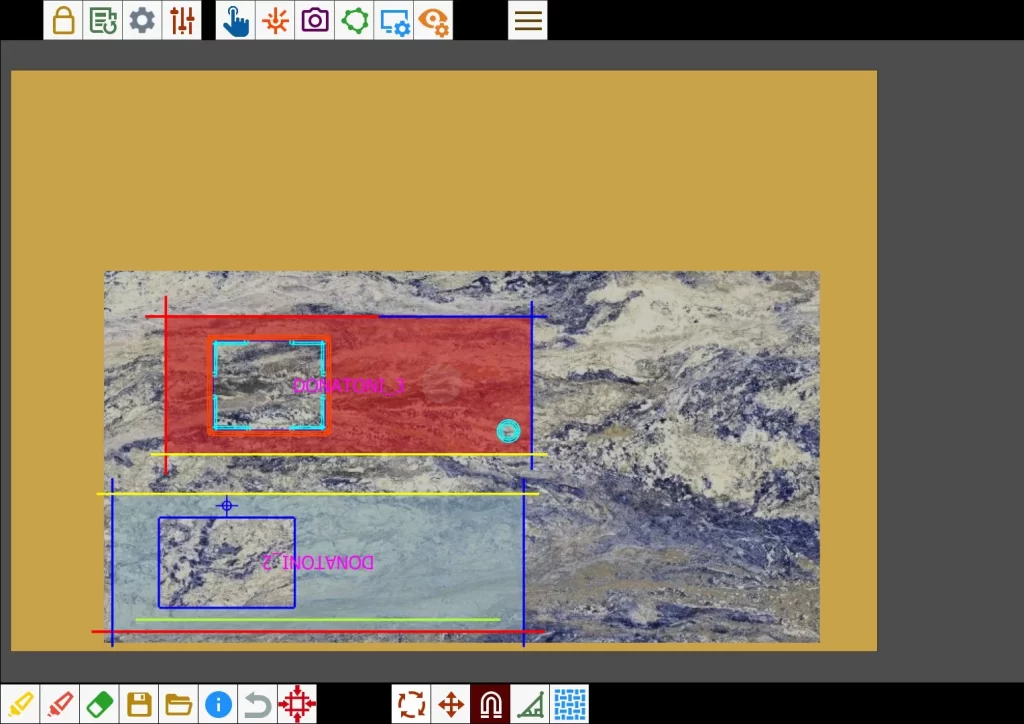

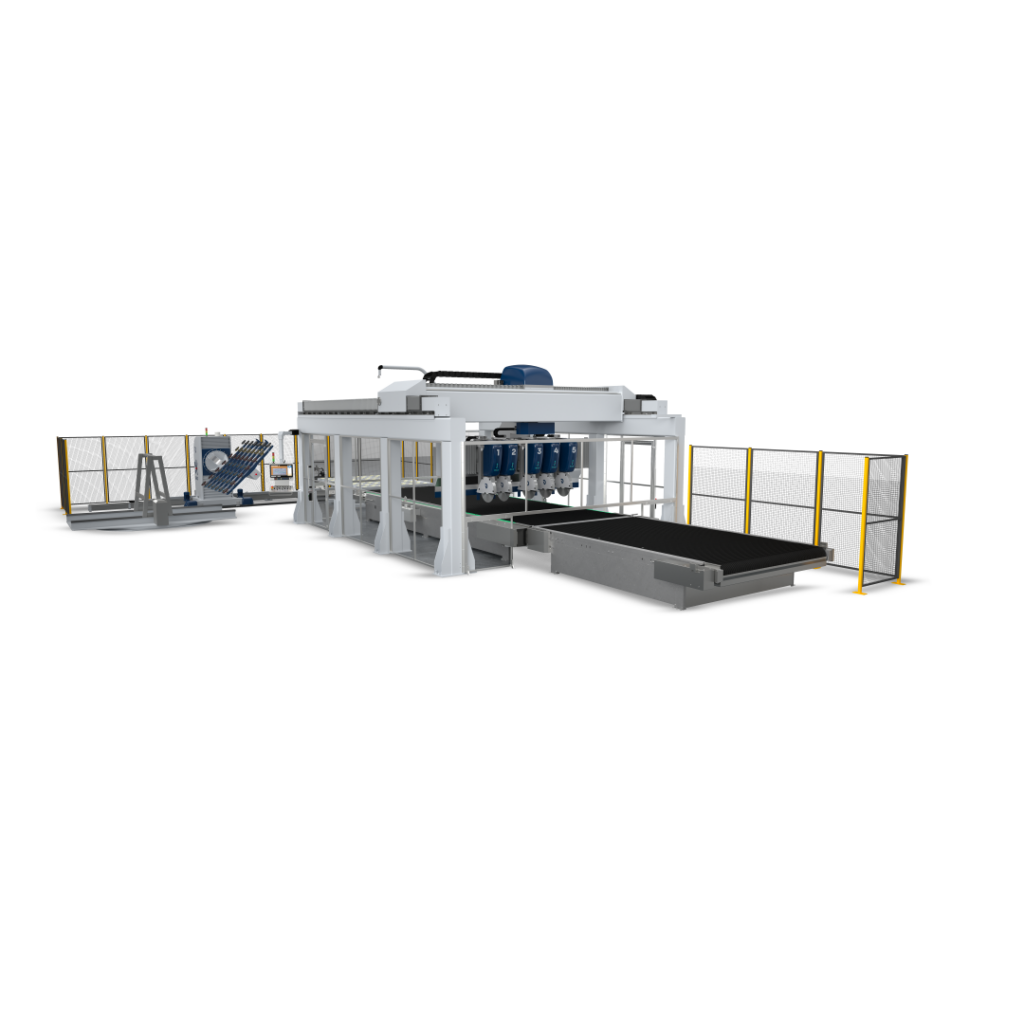

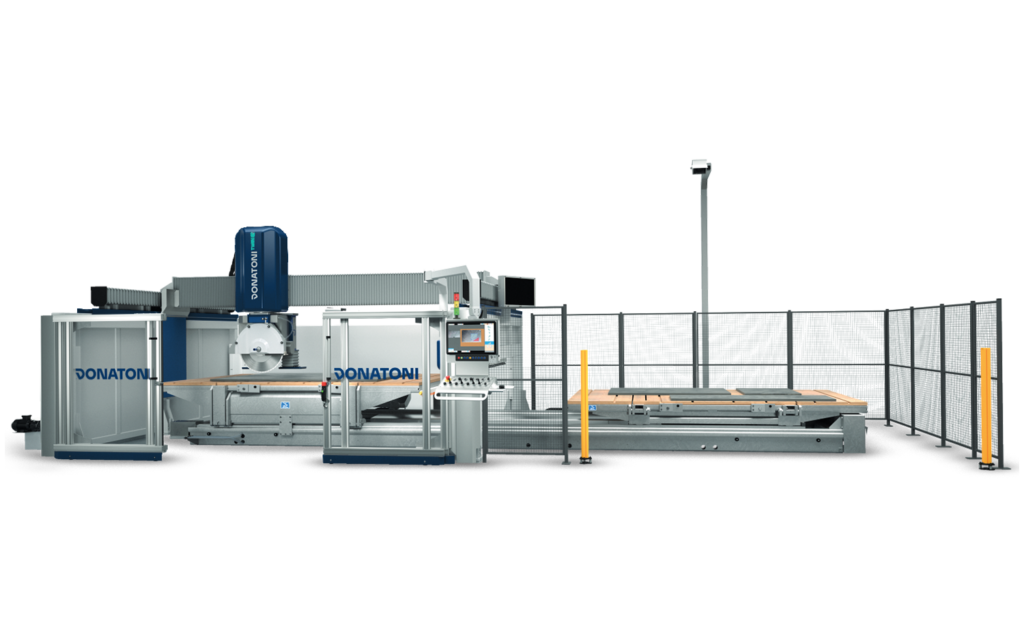

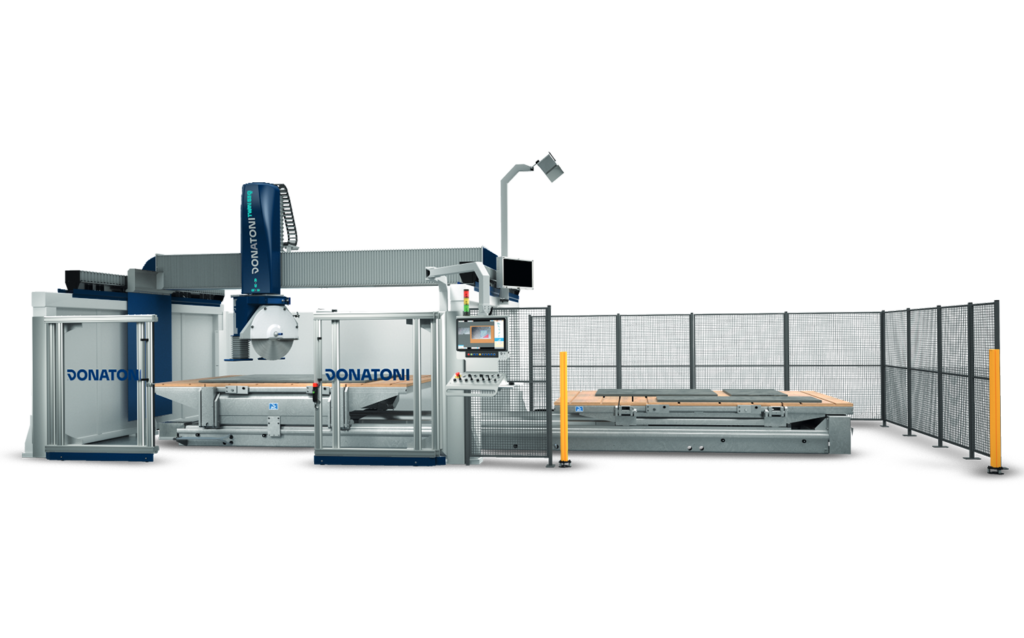

The DONATONI SX-3 Q is an innovative CNC multi-spindle cutting centre with three interpolated 6-axis cutting units,designed, and patented by Donatoni Macchine to satisfy those who require a compact system for the large-scale in-line production of marble, granite, ceramic and agglomerate floor, and wall claddings of various types in different sizes and thickness.

SX-3 Q is equipped with three cutting units with a blade having a maximum diameter of 525 mm to cut up to 150 mm of thickness. The machine is set up on a material transport system which can be single-belt or double-belt (with separate cutting area and unloading area).

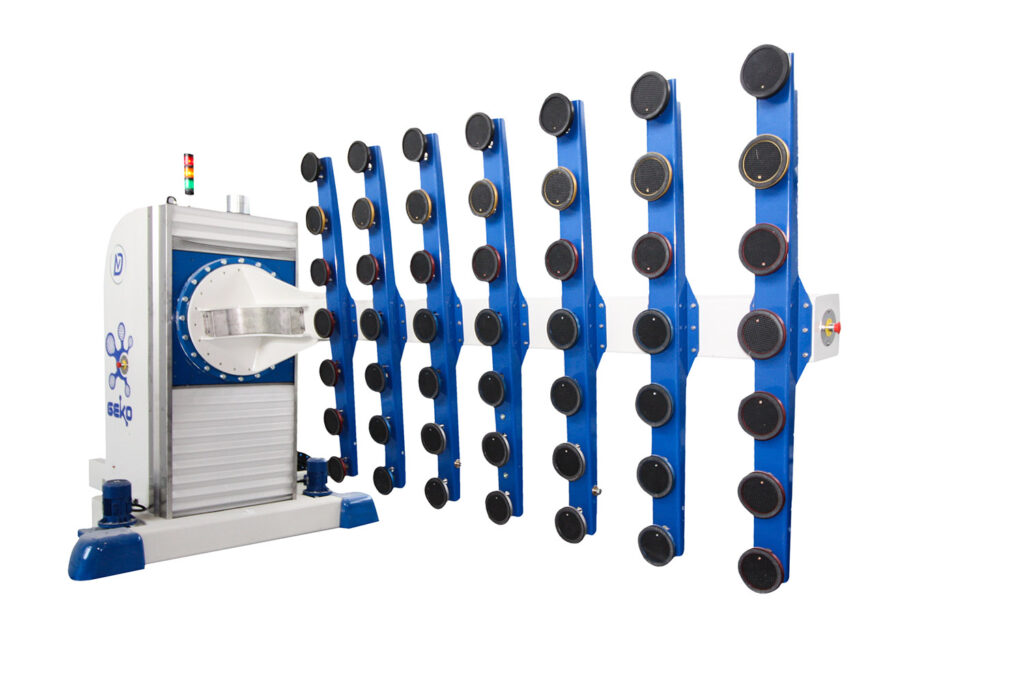

It is an extremely flexible, space-saving, and easy-to-program system that meets the needs of the most demanding customers. The particularly robust construction and oil-bath lubrication of axes X and Y enable this machine to cope with particularly heavy workloads and maintain cutting precision over time. High productivity requires an automatic slab loading system.