Back

Back

What is Parametrix?

Parametrix is the software developed by Donatoni dedicated to the programming and management of machining operations performed with CNC bridge saws, cutting lines, and cutting and shaping centres. Back

Back

Our design softwares

Back

Back

What is D-MES?

The first software platform designed exclusively for the stone industry. Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

Back

ZENITLUX

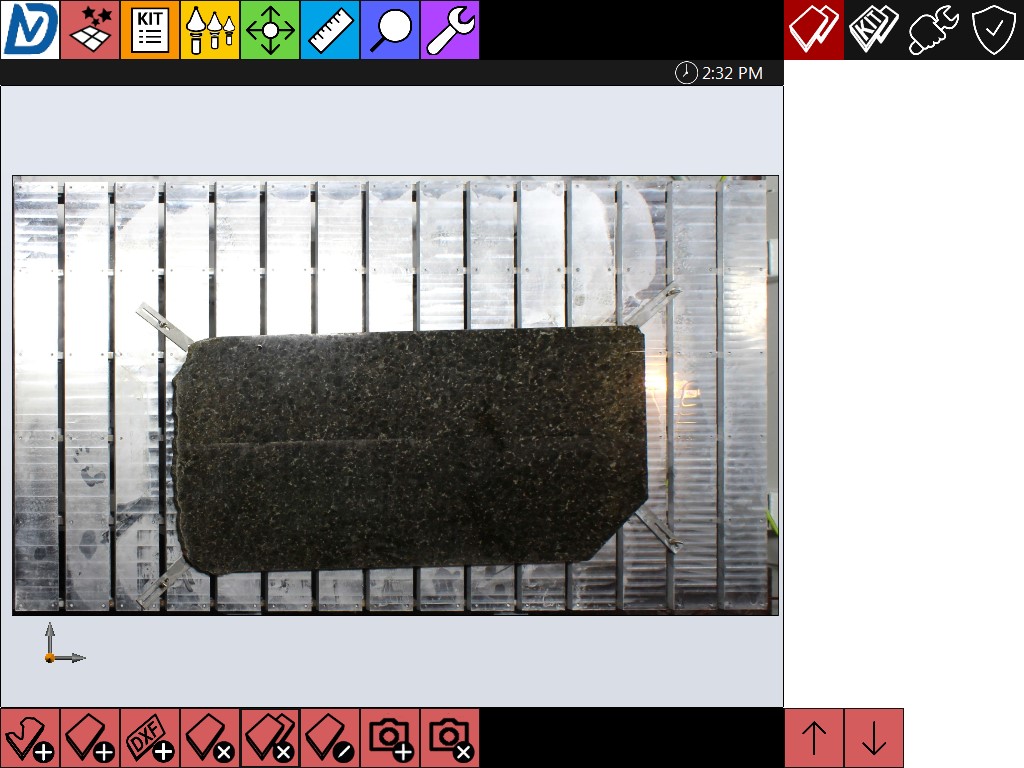

Programming software specifically designed for the DONATONI Zenit machine. It can be used to polish, calibrate, smooth and brush slabs of marble, granite, semi-precious stones and stone in general.

Precise on all types

of surfaces

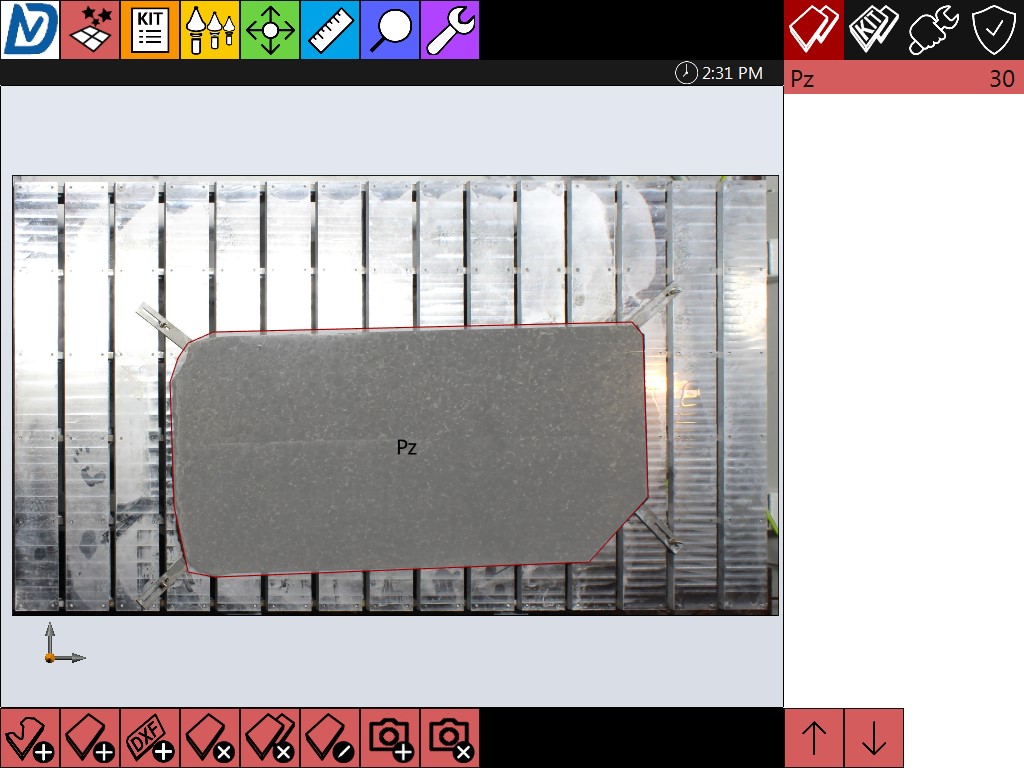

Thanks to the slab camera located on-board, the software allows you to perfectly follow the edges of the slab – even irregular ones – by managing the type of pass you want to make.

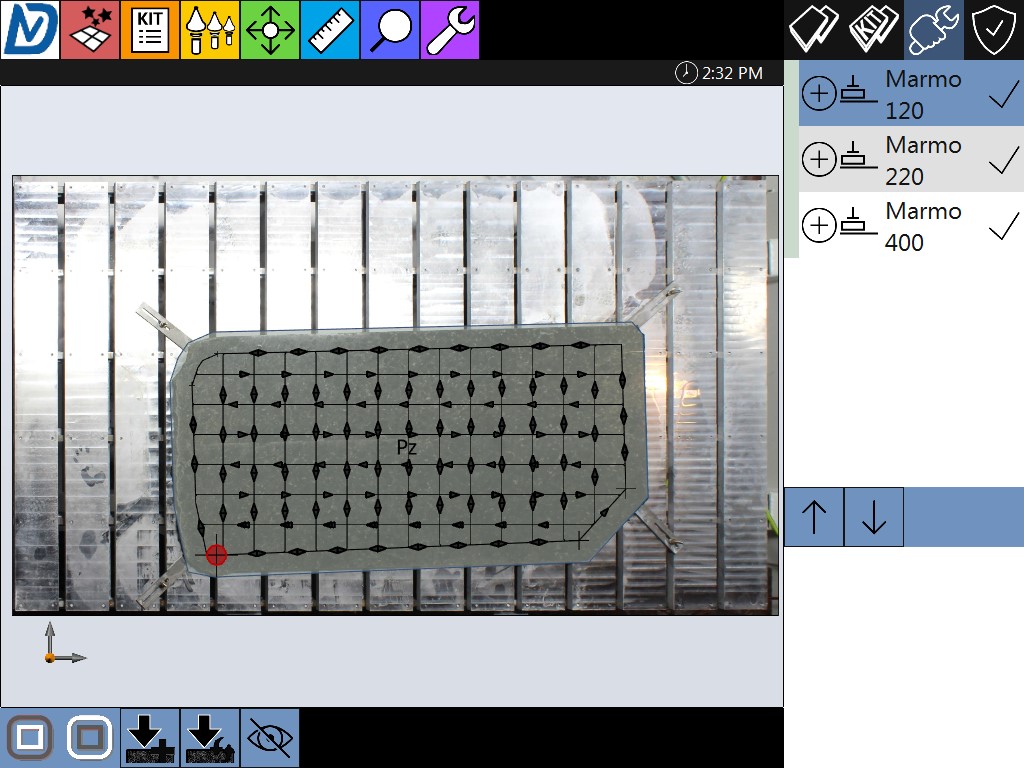

Control and management

During the work process, it is possible to preview the passes and the operator can adjust the pressure according to the type of abrasive and his own experience. Depending on the type of processing, it uses a different pressure system: mechanical for calibration, pneumatic during polishing and smoothing.

View and apply

Zenitlux allows the processing of workpieces of different shapes and thicknesses, loaded onto the workbench at the same time. The operator takes a photo of the work area, identifies the workpieces and applies the desired type of processing to each one.

Using Zenitlux, it is possible to create programs for specific finishes and materials, combining different tools and passes.

Type of passes: